3D Hashin Failure Criteria in Abaqus/Explicit

3D Hashin VUMAT subroutine

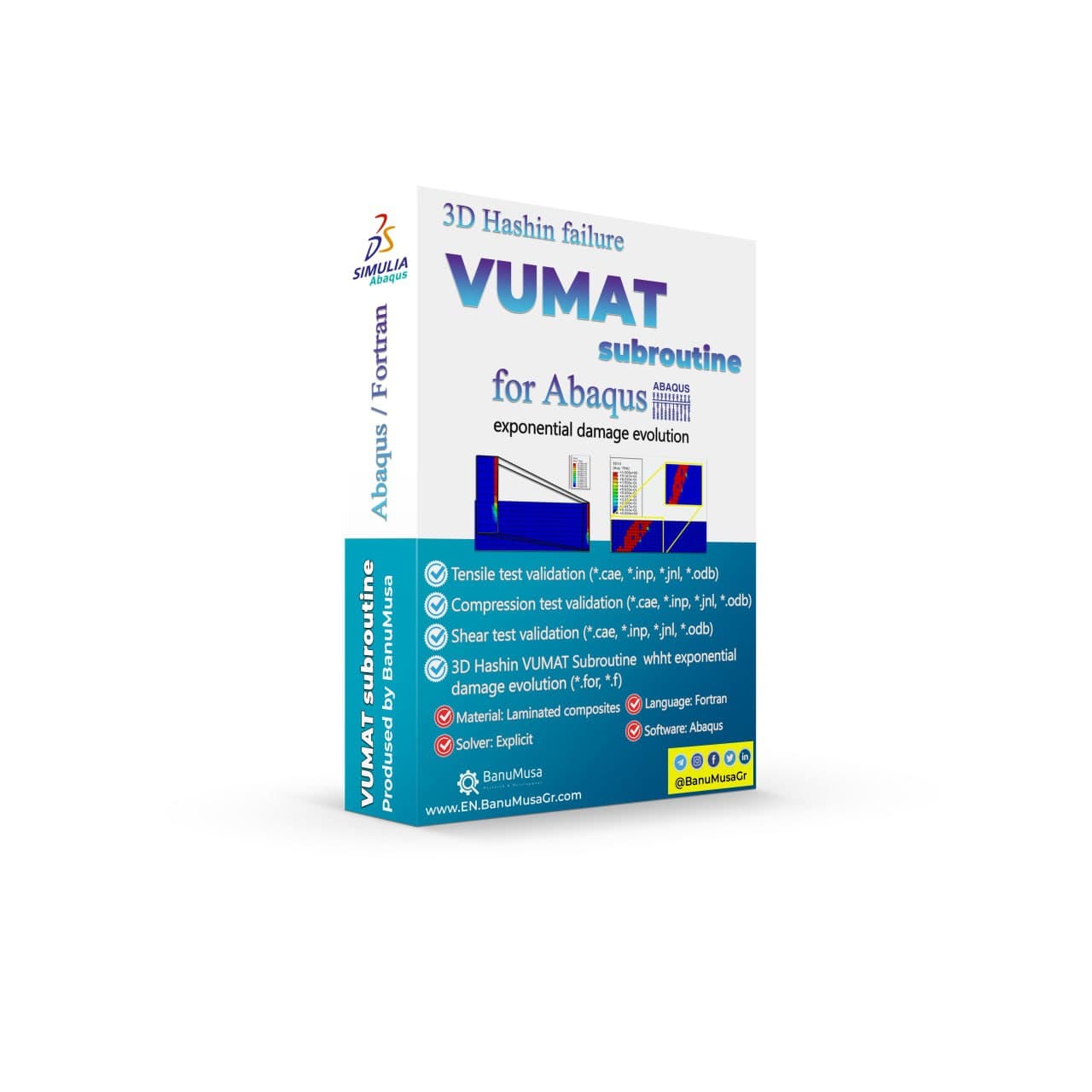

The 3D Hashin VUMAT subroutine is a custom material model developed for simulating composite materials using Abaqus/Explicit. It overcomes the limitations of existing damage models in Abaqus by providing accurate damage modeling capabilities and support for 3D stress states. The subroutine uses exponential damage evolution, which accurately captures the non-linear behavior of composite materials. It can be implemented in Abaqus directly, compiling it, and linking it to an Abaqus input file.

3D Hashin damage model

The ability to accurately predict failure in composite materials is vital for ensuring safety and reliability. The 3D Hashin damage model provides a valuable tool for predicting failure modes, identifying critical regions prone to damage, and estimating the remaining useful life of composite structures.

Why did we develop the 3D Hashin VUMAT subroutine?

In simulating FRP composites using Abaqus, capturing intralaminar damage poses a significant challenge. The available damage models in Abaqus, such as the Hashin damage model and the recently included LaRC05 failure criterion, have limitations in terms of capturing damage evolution and modeling 3D stress states. Specifically, the Hashin model is a 2D damage model that applies to shell-type elements, while the LaRC05 criterion does not yet support damage evolution.

To overcome these limitations, one possible workaround is to develop a custom material model using user subroutines, such as the VUMAT subroutine for Abaqus/Explicit or the UMAT subroutine for Abaqus/Implicit. However, it is important to note that developing robust material subroutines for composites can be complex, requiring a deep understanding of the physics and numerical implementation of damage mechanisms. The heterogeneous nature and anisotropy of composite materials further complicate the task.

Alternatively, there is a high-fidelity constitutive model for composite plies called the 3D Hashin VUMAT Subroutine that has been implemented as a framework of subroutines for Abaqus. Developed by BanuMusa R&D, the 3D Hashin VUMAT Subroutine offers advanced numerical technology and recent modeling features for composites.

Using the 3D Hashin VUMAT Subroutine can provide a ready-to-use solution for simulating composite materials with accurate damage modeling capabilities. This eliminates the need to develop a custom material subroutine from scratch and leverages the expertise and advancements made by the developers at BanuMusa R&D.

Why exponential damage evolution?

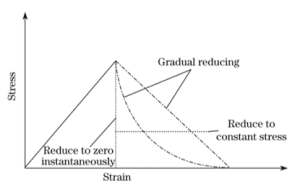

Exponential damage evolution refers to the mathematical formulation used to describe how damage accumulates and evolves in a material. The exponential function is often used to model the degradation of material properties as damage progresses.

When implementation for a stress softening constitutive model, the results are mesh-dependent, e.g., the solution is non-objective concerning the mesh refinement, and the computed energy dissipated decreases with the reduction of the element dimension. Thus, the energy dissipation and characteristic length are introduced into the damage evolution law to reduce the mesh sensitivity.

This model assumes that the damage evolution follows an exponential growth pattern as the material undergoes loading. The exponential damage evolution model is beneficial in capturing the non-linear behavior of composite materials, where damage initiation and growth are highly dependent on the stress state and loading history.

In this code, an exponential function of energies dissipated by damage is established. It can not only describe the progressive development of the damages but also avoid the stiffness matrix singularity due to the material stiffness’s abrupt variation.

VUMAT implementation in Abaqus

VUMAT implementation in Abaqus

To implement the 3D Hashin VUMAT subroutine with exponential damage evolution in Abaqus, several steps need to be followed. Firstly, the subroutine code needs to be written in Fortran (which we did), adhering to the specific syntax and guidelines provided by Abaqus. The code should include the necessary equations for stress-strain calculations, as well as the damage evolution equations based on the exponential model.

Once the subroutine code is written, it needs to be compiled using a Fortran compiler compatible with Abaqus. The compiled subroutine can then be linked to an Abaqus input file, where the composite structure is defined and the analysis parameters are specified. During the analysis, Abaqus will call the 3D Hashin VUMAT subroutine at each integration point to calculate the stress and strain values, as well as update the damage variables based on the exponential model.

Applications and Benefits

Implementing a 3D Hashin VUMAT subroutine with exponential damage evolution opens up numerous possibilities for simulating and analyzing composite structures. This approach can be particularly useful in industries such as aerospace, automotive, and civil engineering, where composite materials are extensively used.

Abaqus application engineers can optimize their designs, improve structural integrity, and ensure safety under various loading conditions by accurately predicting the damage evolution in composite structures. Additionally, this implementation allows for a deeper understanding of failure mechanisms in composites, aiding in material selection and development.

Some other benefits of using the 3D Hashin VUMAT Abaqus Subroutine developed by BanuMusa R&D include:

- Allows for the use of 3D solid elements in simulating the damage of FRP composite materials with an explicit solver.

- Considers four different modes of failure: fiber rupture in tension, fiber buckling and kinking in compression, matrix cracking under transverse tension and shearing, and matrix crushing under transverse compression and shearing.

- Utilizes an exponential damage evolution based on Linde (2004), providing a more accurate representation of damage progression.

Compatible with the Abaqus explicit solver.

How does the damage initiation in the 3D Hashin VUMAT Abaqus Subroutine differ from the Abaqus built-in Hashin model?

The Abaqus built-in Hashin damage initiation criterion can only be used with elements that have a plane stress formulation, which includes plane stress, shell, continuum shell, and membrane elements. It cannot be used with 3D solid elements. In contrast, the 3D Hashin VUMAT Abaqus Subroutine developed by BanuMusa R&D uses the Hashin (1980) and Maximum stress criteria for damage initiation.

The damage evolution in the BanuMusa VUMAT subroutine is also different, using an exponential function based on Linde (2004) instead of a linear function used in the Abaqus built-in Hashin model.

Verification & validation (V&V)

Verification and validation (V&V) are crucial processes in the development of any product or system. These processes are used to ensure that the product or system meets the specified requirements and is fit for its intended purpose.

Verification involves checking that the product or system is being built according to the requirements and design specifications. This can include activities such as reviews, inspections, and walkthroughs to ensure that the development process is on track.

Validation, on the other hand, involves evaluating the final product or system to ensure that it meets the user’s needs and expectations. This can include activities such as testing, user feedback, and acceptance criteria to ensure that the product or system is fit for its intended purpose.

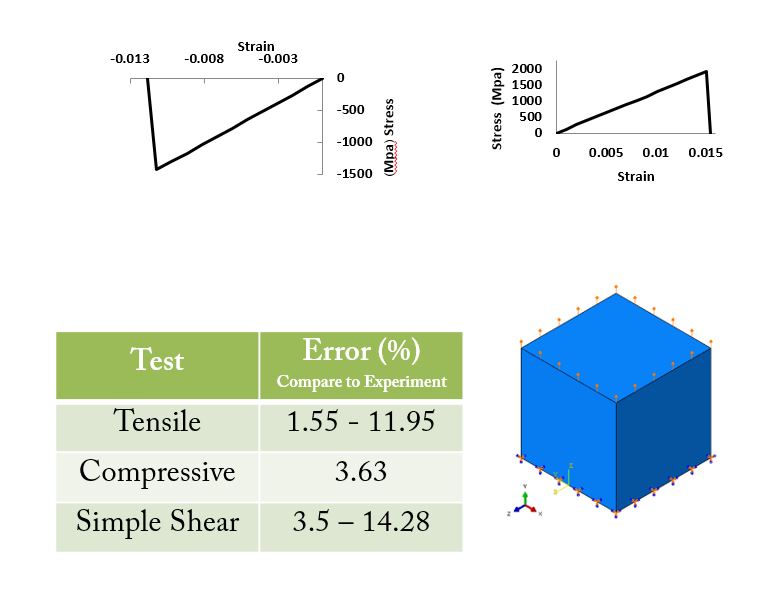

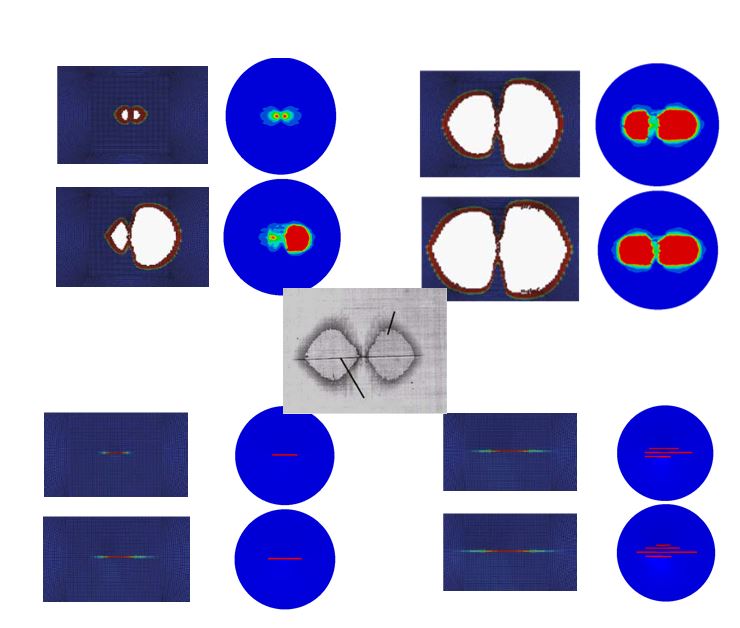

Single element test

Single element test

Abaqus subroutines require single element tests to ensure the accuracy and reliability of the code. By conducting tests on a single element, engineers can verify that the subroutine behaves as expected and produces the correct results for a simple case before applying it to more complex models.

Single element tests also help to identify any errors or issues in the subroutine’s implementation, allowing developers to debug and refine the code as needed. This process ultimately leads to a more robust and trustworthy subroutine that can be confidently used in a wide range of finite element simulations.

- Tensile

- Compressive

- Simple Shear

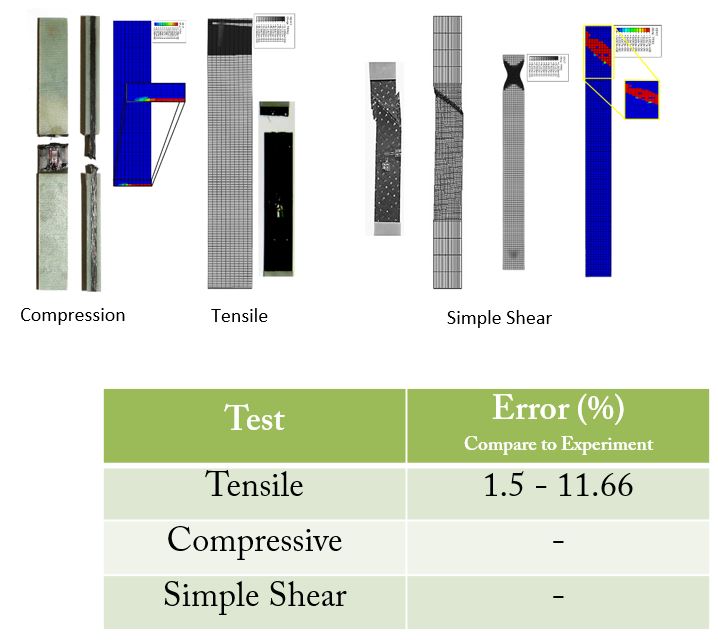

ASTM specimen test

ASTM specimen test

Abaqus subroutines require ASTM specimen test validation for several reasons. Firstly, validation ensures that the material models and elements used in the simulation accurately represent the behavior of real materials under various loading conditions. This is crucial for obtaining reliable and accurate results from finite element analysis.

Additionally, validation against ASTM specimen tests provides confidence in the accuracy of the simulation results, which is essential for making informed engineering decisions. It also helps in verifying the implementation of material models and elements within the Abaqus software, ensuring that they adhere to industry standards.

- Tensile

- Transverse Tensile (ASTM D3039/D3039M-08)

- Compressive

- Simple Shear (ASTM D3518/3518M-94)

Low-velocity impact validation

Low-velocity impact validation

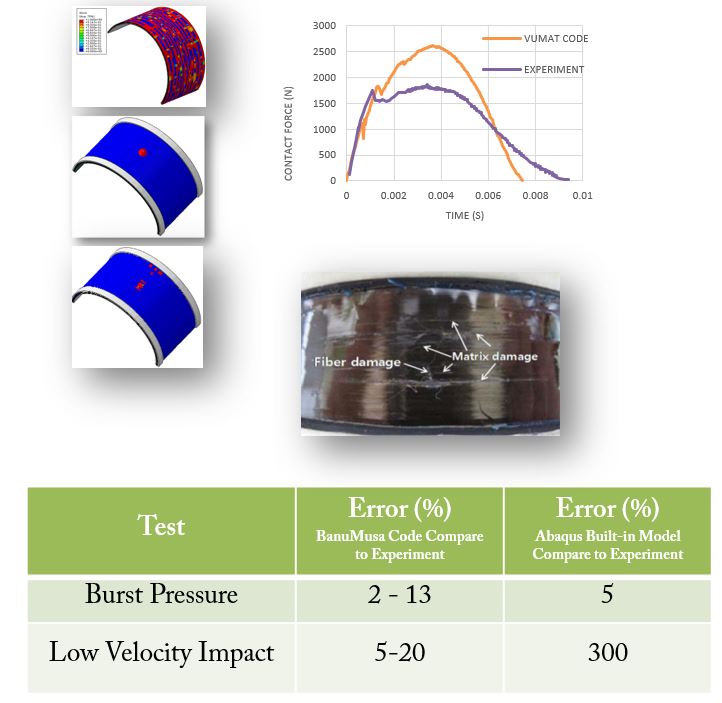

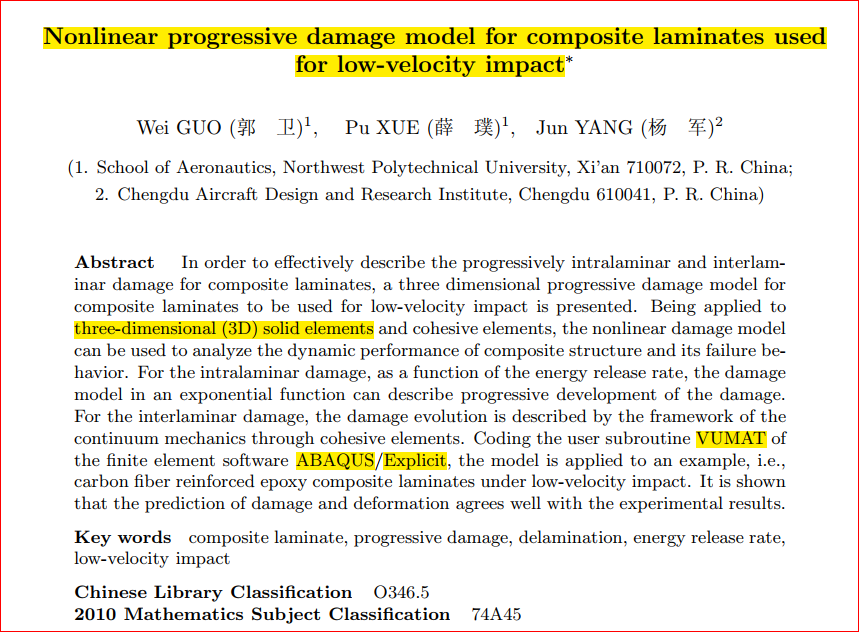

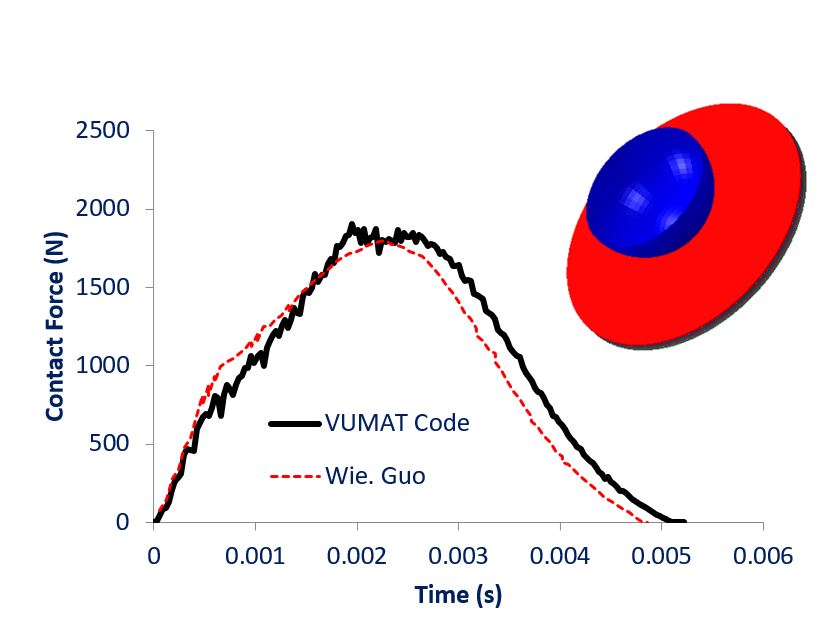

To validate the performance of the VUMAT code, the low velocity impact test results were compared with the results presented in Guo et al. paper.

- Contact Force

- Damages

- Interlaminar (Delamination)

- Intralaminar

Composite Pressure Vessel (COPV)

- Burst pressure analysis of COPV

Burst pressure analysis involves evaluating the maximum pressure that a COPV can withstand before rupturing. This is crucial for determining the operational limits and safety margins of the vessel. Factors such as material properties, manufacturing processes, and environmental conditions are taken into account during the analysis. - Low-Velocity Impact analysis of COPV according to ASME Sec. X

This analysis helps to assess the vessel’s response to potential impact scenarios, such as mishandling during transportation or minor collisions.

- Burst pressure analysis of COPV

BanuMusa 3D Hashin VUMAT Abaqus Subroutine Benefits

Special features

3D Hashin VUMAT Abaqus Subroutine

Need help? Get a consultation from our experts.

Telegram: +98-915-55-20-388

WhatsApp: +98-915-55-20-388

Find Us on WeChat

VUMAT implementation in Abaqus

VUMAT implementation in Abaqus Single element test

Single element test ASTM specimen test

ASTM specimen test Low-velocity impact validation

Low-velocity impact validation

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

Emmett –

Great post. I was checking constantly this blog and I’m impressed! Extremely useful info specially the last part 🙂 I care for such info much.

I was seeking this certain information for a very long time.

Thank you and good luck.