Stress Analysis of UIC60 Rail Wheel under Rolling Contact Fatigue Conditions

Rolling Contact Fatigue

Rolling Contact Fatigue

Rolling contact fatigue is a complex failure mechanism that can occur in wheel-rail contact under repeated cyclic loading. Some key points regarding the stress analysis of rolling contact fatigue in wheels:

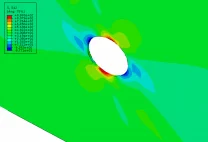

- Hertzian contact stress – The most important stress is the maximum Hertzian contact stress that occurs at the contact patch between the wheel and rail. This stress depends on the normal load, wheel, and rail geometry, and material properties.

- Tangential forces – The presence of tangential forces due to traction and braking produces shear stress at the contact patch, which contributes to rolling contact fatigue.

- Subsurface stress – The Hertzian contact stress produces high subsurface shear and principal stresses that can exceed the material yield strength. These subsurface stresses are critical for crack initiation.

- Crack initiation and propagation – Cracks typically initiate at the subsurface and grow in a direction perpendicular to the maximum principal stress. Multiple crack initiation sites are possible.

- Residual stresses – Residual stresses due to fatigue, wear, and rolling contact can significantly affect the stress state and fatigue life. They need to be considered in the analysis.

- Parameters to vary – Important parameters to vary in the stress analysis include normal load, tangential forces, wheel and rail material, wheel profile, rail profile, and operating conditions.

Advanced finite element analysis with proper contact modeling and considering parameters like residual stresses can provide detailed insights into the stress state and rolling contact fatigue failure mechanism. This Abaqus tutorial discusses the effect of axial force, velocity, and rail gap angle parameters on the distribution of contact and impact stresses.

Train Accidents Caused by Rolling Contact Fatigue

Rolling contact fatigue is damage that accumulates in rails and wheels due to the repeated rolling and sliding contact between them. It causes cracks and fractures to form, especially at the surface. Rolling contact fatigue is an important failure mode for rails and train wheels that can lead to accidents if not properly managed.

Some notable rail accidents that have been attributed at least in part to rolling contact fatigue:

Need help? Get a consultation from our experts.

Telegram: +98-915-55-20-388

WhatsApp: +98-915-55-20-388

What you’ll learn

- Modeling the cross-section of the rail profile (UIC60) from the image and making a 3D deformable part

- Importing a 3D part to model

- Using virtual topology tools to modify geometry and better meshing

- Applying the material properties, density, elasticity, and plastic of steel

- Applying point mass to a part

- Using the dynamic explicit step, using mass scaling to increase the solution speed

- Selecting suitable and practical outputs

- Defining behavior and contact characteristics

- Making a rigid body with a simple method

- Using Tie constraint and its tips

- Coupling and how to rotate the wheel on the railway

- Applying gravity load

- Applying boundary conditions (BC)

- Meshing techniques

- Visualization and interpretation of the results

UIC60 Rail Profile

UIC60 Rail Profile

UIC60 (60E1) is a standardized heavy rail profile developed by the International Union of Railways (UIC) primarily for use in European and some Asian railway networks. The dimensions, geometry, and weight are optimized to provide strength, durability, and compatibility for higher-load railway operations. This rail profile was standardized by UIC in 1976.

Who this course is for

- Rail and mechanical engineers who need to perform stress analysis

- Advanced students, Ph.D. students, or researchers for their Abaqus FEA projects

- Any Abaqus Application Engineer who is involved with various simulation projects on a daily basis

What you’ll gain

- You will be able to perform failure analysis by Abaqus

Rolling Contact Fatigue

Rolling Contact Fatigue We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at  UIC60 Rail Profile

UIC60 Rail Profile

Hans –

Hi it’s me, I am also visiting this website on a regular basis, this web page

is genuinely nice and the people are in fact sharing nice thoughts.