Design / process optimization

Combining and using different software to optimally design products requires significant time to transfer data and results in different software. A software package that automates data transfer operations and results between engineering software and implementation of design optimization with different optimization methods will be of great help to the product design team. The software that performs this operation is called process integration and design optimization (PIDO) software. The advantage of using this software, creating a workflow in the design and simulation process, reducing human errors during data transfer and results between software, speeding up the optimization process by automating this process, no need for additional coding for link two Software, and the existence of many other benefits that this type of software has considered.

Combining and using different software to optimally design products requires significant time to transfer data and results in different software. A software package that automates data transfer operations and results between engineering software and implementation of design optimization with different optimization methods will be of great help to the product design team. The software that performs this operation is called process integration and design optimization (PIDO) software. The advantage of using this software, creating a workflow in the design and simulation process, reducing human errors during data transfer and results between software, speeding up the optimization process by automating this process, no need for additional coding for link two Software, and the existence of many other benefits that this type of software has considered.

iSight Software

Isight software is a process integration and design optimization (PIDO) software that can be used to integrate various applications. Using the site, engineers and researchers can make the simulation process more flexible and enable the design process of the process by automating design choices to determine the most optimal parameters for the desired performance.

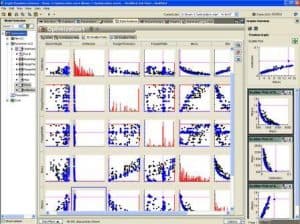

Experimental design

To design the experiment, various methods such as Central Composite, Data File, Full Factorial, Fractional-Factorial, Box-Behnken, Latin Hypercube, Optimal Latin Hypercube, Orthogonal Array, Dependent Variable Sampling, and Parameter Study can be used in the software and for each, A facility has been built into better view the results.

Optimization

The following algorithms can be used to define optimization:

- Gradient: NLPQL, MMFD, LSGRG2

- Pattern: Hooke-Jeeves, Downhill Simplex, Adaptive Simulated Annealing

- Mixed Integer / Real: MISQP, MOST

- Genetic Algorithms: Evolution, Multi-Island GA

- Multi-Objective: AMGA, NSGA II, NCGA, Particle Swarm

- Other: Stress-Ratio Method, Pointer I & II Automatic Optimizer, Multi-objective approximation Loop

Abilities

- Automate a series of functions in the simulation process

- Increase and decrease design components

- Coupling different CAD and CAE software in the design process

- Using Excel software

- Implement design optimization using various techniques such as Experimental Design (DOE), Optimization, Monte Carlo, 6Sigma Method, Taguchi, and…

- Integration of Abaqus, Ansys, LS Dina, StarCCM, ADAMS, NASTRAN, and much other software

- Use a wide range of applications for use in the workflow