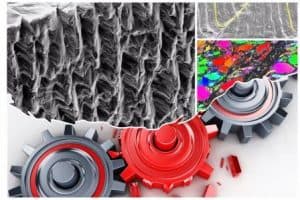

Failure Analysis

Failure analysis is the process of determining why and how equipment or components fail. It is used to:

- Determine the root cause of the failure

- Identify design flaws or manufacturing defects

- Prevent future failures by understanding failure modes and mechanisms

A typical failure analysis involves:

- Inspection – Closely examining the failed component or equipment to look for visible signs of damage, wear, corrosion, overheating, cracks, etc. Taking photos during inspection can also be useful.

- Data collection – Gathering any relevant operational data, maintenance records, manufacturing details, specifications, and test results related to the failed component. This provides context for the failure.

- Testing – Performing non-destructive and/or destructive tests on the failed component to gather more information. This can include things like electrical tests, environmental tests, metallography, and chemical analysis.

- Analysis – Analyzing all the collected data, inspection results, and test data to determine the most probable root cause(s) and failure mechanism(s). This often requires consulting with subject matter experts.

- Reporting – Documenting the results of the failure analysis in a report that details the probable root cause, failure mechanism, contributing factors, and recommendations to prevent future similar failures.

In BanuMusa R&D, various methods are used to determine the causes of the failure of materials and structures. We are active in various fields of engineering such as mechanics, engineering materials, manufacturing, solids and fluids, heat transfer, multiphysics, and other specialties required for analysis of Malfunction of materials and structures.

Failure Analysis of Metal Materials

The failure analysis of metal materials has a great impact on the production cycle of various products. Corrosion and impurities of materials cause rapid deterioration of medical and industrial equipment. According to an international organization, corrosion of metals causes about $ 300 billion in damage to industry each year. In BanuMusa R&D, fatigue, impact, and corrosion tests are performed.

Failure Analysis of Composites Materials

Composites are complex materials with multiple failure modes, so a thorough failure analysis examines all relevant material, manufacturing, and usage factors that could have contributed to or caused the failure. A detailed record of findings and recommendations can then be made to improve designs, processes, and use of the composite material going forward.

Here are some key considerations for the failure analysis of composite materials:

- Types of failure – Composites can fail in a variety of ways like fiber breakage, matrix cracking, delamination, and debonding. Understanding the different failure modes is important.

- Fiber properties – Examining the properties of the fibers used, like fiber strength, modulus, orientation, and weight fraction. Fibers often govern the strength of the composite.

- Matrix properties – Analyzing the properties of the matrix material, like its mechanical properties, chemical resistance, and ability to transfer loads to the fibers.

- Interface properties – Evaluating the bond or interface between the fibers and matrix. Weak interfaces can lead to delamination and debonding failures.

- Manufacturing defects – Looking for possible defects introduced during manufacturing of the composite like voids, fiber misalignment, ply wrinkling, incorrect fiber volume fraction, etc.

- Environmental effects – Determining if exposure to moisture, heat, chemicals, or radiation contributed to the failure. Composites can degrade over time in certain environments.

- Loading conditions – Understanding the types of loads and stresses the composite was subjected to. Composites often have directionally dependent properties.

- Residual stresses – Checking if residual stresses from manufacturing were present and if they contributed to failure initiation or propagation.

- Material variations – Ensuring material properties were consistent throughout the composite part. Variations in resin or fiber content can create weaknesses.

- Inspection – Closely examining the failure region at multiple length scales using microscopy, radiography, and another nondestructive/destructive testing.

- Testing – Performing standardized tests like tension, compression, flexure, and shear on samples to determine the properties and failure stresses of the composite.