Automotive

The current state of the automotive industry in the world shows that long-term contracts have increased. The number of manufacturers has declined, and in the future of the automotive industry, the company will only be able to market its products where they compete based on quality, engineering abilities, and delivery on time.

Today, advanced countries have industry, technology, and market manufacturing because of the high value-added in the automotive industry and leave low value-added industries to less developed countries.

The first stage for producing global-level parts is the detailed design and conformity to the standards of the world. One of the tools available to engineers in the automotive industry is to use numerical simulation to design, manufacture, and deploy parts.

By using numerical simulation, the behavior of the structure before construction will be predictable, and in case of the need for modification and changes in the same design, the stage can be done. Nowadays, a wide range of phenomena, engineering, and physical problems can be investigated using numerical simulation.

Some of the advantages of numerical simulations in the automotive industry include:

Design optimization

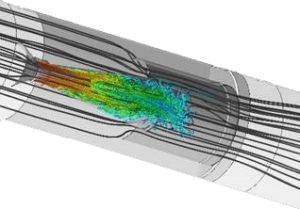

Numerical simulations allow automotive engineers to optimize vehicle designs, including components such as engines, chassis, and aerodynamics, leading to improved performance and fuel efficiency.

Cost savings

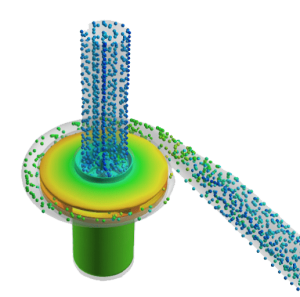

Simulations can reduce the need for physical prototypes and testing, saving time and resources during the design and development process using FEA and CFD.

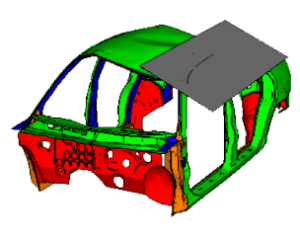

Safety testing

Simulations enable the assessment of vehicle safety features and crashworthiness without the need for physical crash tests, contributing to improved vehicle safety.

- Airbag

- Roof impact

- Direct accident

- Dummy modeling

Performance analysis

Simulations can be used to analyze vehicle performance under various conditions, such as different driving scenarios and environmental factors, aiding in the development of better-performing vehicles.

Environmental impact assessment

Numerical simulations can help evaluate the environmental impact of vehicles, including emissions and energy efficiency, supporting the development of more sustainable automotive technologies.

Virtual testing

Simulations allow for virtual testing of vehicle components and systems, helping to identify potential issues early in the design process and improving overall reliability.

According to Fortune magazine, most successful companies in the world use virtual simulations to compete with other firms.

In this regard, BanuMusa R&D is prepared to offer the following services to the automotive industry:

- Vibrations and noise

- Car dynamics

- Reliability and fatigue

- Failure analysis

- Aerodynamics and computational fluid dynamics

- Wind tunnel

- Heat transfer and passenger comfort

- Multi-physics

- Metal forming

- Structures and materials

To design and simulate different parts and processes, many engineering software is available that the engineers of the BanuMusa R&D are capable of working with. Some of the most important of these are as follows:

- MSC ADAMS

- AVL Workspace

- ABAQUS

- Ansys

- CATIA

- Solidworks

- AutoCAD

- LS Dyna

BanuMusa Co. can be your partner in the implementation of projects related to the automotive industry. So please contact us.