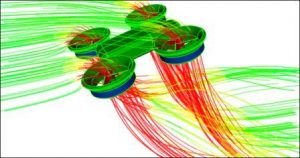

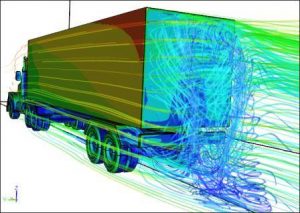

Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics: Uniform and turbulent flows, Newtonian fluids, multiphase flows such as phase change of materials, lubrication films, and microfluidics are the most important issues in the field of CFD simulation.

Simulation and validation of various fluid problems or structural-fluid interactions in industrial equipment and parts are accepted.

Our company’s engineers have graduated from the best universities in the country and have simulated and analyzed various projects using the CFD method. Complex engineering issues such as fluid coupling and structure or fluid and temperature are applicable in this company.

Problem Application

Layered and turbulent flow medical equipment, biotechnology, pharmacy

Structural-fluid interaction marine industries, renewable energy, energy conversion

Heat and mass transfer industrial processes

Multiphase flow hydraulic and pneumatic systems, heaters, and boilers

Flow in a porous body consumer equipment, food industry

Surface tension and wetness pumps, valves, and nozzles

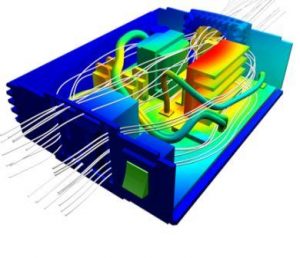

Acoustics Cooling of electronic equipment, heat management in devices

Company capabilities

Analysis, modeling, and simulation of a cell flow with surface effect, micro-instrumental slide, biology-inspired refrigeration, heat exchangers, pressure due to martagon and curved currents, structural-acoustic vibrations, electro-kinetic currents, droplet and bubble currents, Electromagnetic heating, spray, heat-fluid coupling, conjugate heat transfer, the calculation for and after, particle transfer and sorting, pipe network, phase change, fluid composition, multiphase currents in fibrous materials, wick, non-newton currents, compression currents Acceptable.

Result

What is expected at the end of the simulation and analysis using the CFD method includes the following:

- Understand product performance

- Product design optimization

- Prove the conceptual design efficiency

- Possible design troubleshooting

- Achieve new ideas

- Innovation in product design and production

Softwares

- Ansys Fluent

- Ansys CFX

- OpenFoam

- Star ccm +