Oil and Gas

The oil and gas industry is one of the most important industries in the world. The costs incurred by the industry in the exploration and extraction processes are considerable and significant. Costs can be greatly reduced by applying numerical simulation in this industry. Using linear and nonlinear solutions and explicit and implicit methods, Multiphysics analysis including temperature, temperature-stress, etc., as well as analysis of various loads such as wave, buoyancy, flow, and wind force in simulation processes in the oil and gas industry are very important.

There are many applications in the oil and gas industry, including rubber, plastic, metals, minerals, composites, etc. The simulation and analysis of these materials require a great deal of expertise.

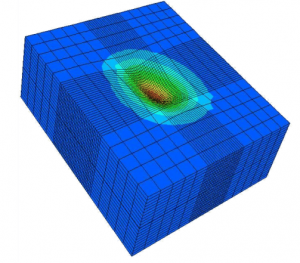

Bedrock Analysis

Analyzing the bedrock can improve the estimation of hydrocarbon production and prevent potential breakdowns due to corrosion. Corrosion-displacement couplings, properties of soil elements, damage and fracture prediction, and more can be studied here.

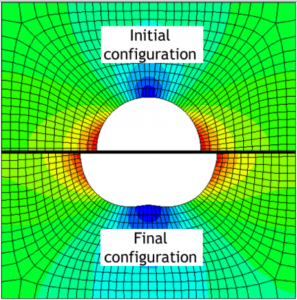

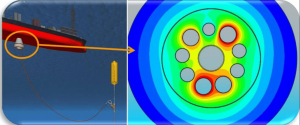

Hydraulic Fracture

Hydraulic fracture tests can accurately assess hydraulic fracture rates and use appropriate technologies to counteract them. Fracture surface modeling, tangential and vertical currents, and corrosion-displacement coupling are among the analyses that can be used in this area.

Abaqus Example: Hydraulically induced cracks near an oil-well bore hole

Pipelaying Analysis

Process of evaluating and planning the installation of pipelines. This analysis involves assessing factors such as the route, depth, materials, and methods used for laying the pipelines.

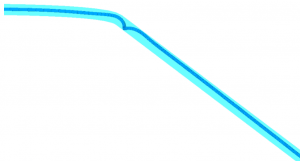

Reeling Analysis

Process of analyzing the feasibility and planning of reeling operations. In the context of pipelines, reeling involves winding a flexible pipe onto a reel for transportation or installation. The analysis may include factors such as pipe material properties, reel capacity, installation method, and environmental considerations. The analysis aims to accurately model the movement, stresses, and deformations experienced by the pipes and cables during reeling.

Fatigue Analysis

Fatigue analysis involves assessing the durability and lifespan of materials or structures subjected to cyclic loading. Strain-based fatigue calculations focus on predicting the fatigue life of components based on the strains they endure during loading cycles, rather than just stress levels.

Using SIMULIA fe-safe, engineers can conduct precise Strain-Based Fatigue calculations for components exposed to complex and random loading conditions. This software tool enables accurate evaluation of how materials will perform over time under varying loads, helping to identify potential fatigue issues and optimize component design for enhanced reliability.

Rubber Analysis

By employing precise hyperelastic material models, engineers can effectively characterize and anticipate the behavior of rubber components such as gaskets, seals, and friction pads.

Hyperelastic material models are advanced mathematical representations used to capture the nonlinear elastic properties of materials like rubber, which can experience significant deformations. These models enable accurate prediction of how rubber components will respond to different loads and environmental conditions.

Wear and Erosion Analysis

One of the things that are very important in the oil industry is the production of sand during the extraction. Problems with sand production can include:

- Erosion of equipment such as pipes, pumps, valves, etc.

- Blocking of surface and inside equipment such as pipes

- Needing more manpower to replace and repair equipment and well-cleaning

- Reduction of formation permeability followed by a reduction in reservoir recycling efficiency.

By analyzing and estimating sand erosion and production, we can determine the techniques of sand control with greater confidence. Also, designing and analyzing sand control methods can significantly save money on designing new and advanced ESSs.

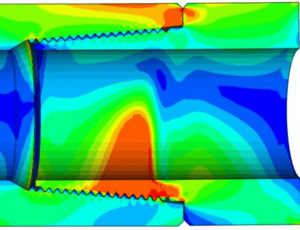

Pipes Torsion

This simulation can prevent possible torsion of the tubes or predict the location of torsion. This process requires real modeling of good geometry and pipe coupling, which requires the use of nonlinear solutions, such as friction and contact.

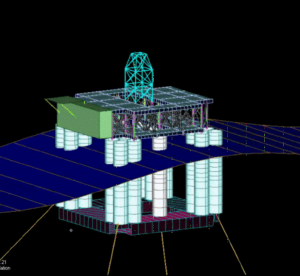

Offshore Modeling

Different offshore structures are subject to different loads, such as wind and wave loads. Explicit and implicit solutions are used to simulate these structures to achieve results such as improved strength, stability, and safety under different loading conditions, including sudden loads.

Heat Management

Designing suitable solutions for cooling emblems and developing insulation to maintain pipeline flow under operating conditions and sudden failures are the benefits of thermal simulation in the oil and gas industry. Some of the analyses that can be done in this regard are FSI analysis in structures, radiation heat transfer analysis, and contact analysis.

The breakdown mechanism of threaded joints can lead to the production of joints to withstand further pressures in the oil and gas industry.

And many other simulations, including:

- Waveloading Analysis

- Bolt Load Analysis

- Gasket Analysis

- Crack Propagation Analysis

- Contact Analysis

- Buckling Analysis

- Frequency Analysis

- Seals & Bearing Analysis

- Handling & Hoisting analysis

- Explosion Safety Analysis

- Soil Structure Analysis

- Geomechanics Analysis

- Failure Analysis

- Concrete Failure Analysis

- Composite Analysis

- Analysis of rotating parts

- CFD Analysis

- FFS Analysis

- Acoustic and Noise Analysis