Aerospace

According to reports released by the airline, flying a plane always costs several millions of dollars to cause damage to the aircraft body as well as timetable changes for those companies. Experimental simulations of bird impact in the aerospace industry are part of the tests to be performed for some aircraft components and parts while designing. Performing this process numerically will reduce the cost of prototyping.

Our company is structured in such a way that it is fully familiar with the rules and requirements for the design of aerospace industry structures. Our service covers a wide range of aerospace industry and related industry needs and can be considered your professional design office.

Advanced material analysis is an important part of our work at BanuMusa. Structural health assessment and failure analysis of composite and non-composite materials including crack and crack growth are covered in this section.

In the simulation of the manufacturing process, the goal is to produce solid, lightweight components. The production process is fully simulated using reliable software in this field to accurately evaluate the thermomechanical effects, heat transfer, and other parameters that affect the production of a high-quality piece.

In the simulation of the manufacturing process, the goal is to produce solid, lightweight components. The production process is fully simulated using reliable software in this field to accurately evaluate the thermomechanical effects, heat transfer, and other parameters that affect the production of a high-quality piece.

Reliability assessment is another part of our service that needs to be followed in designing high-security structures and equipment. Our experts are capable of performing GAP and FMECA analyzes.

Our service in this field

- Geometric modeling

- Static and Dynamic Analysis

- Fluid and Structure Interaction (FSI)

- Combustion simulation and thermal analysis

- Component Optimization

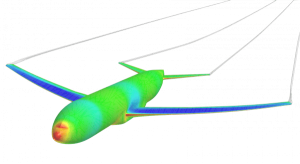

- Simulation of emergency landing on the water surface

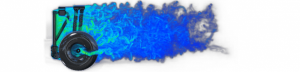

- Simulation and Analysis of Low Speed and High-Speed Impact

- Design based on the minimum weight

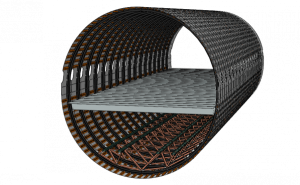

- Design of composite parts

- Simulation of mechanisms

- Structural design of wing and tail

- Buckling Simulation and Analysis

- Explosion simulation and analysis

- Analysis of structural failure, damage, and failure

- Damage analysis of composite materials

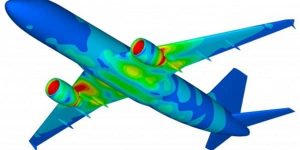

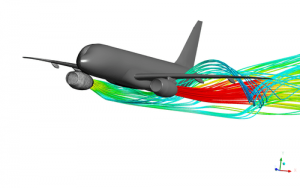

- Aerodynamic analysis using the CFD method

- Corrosion Simulation and Analysis

- Structural and fluid interaction analysis

- Simulation and noise analysis using the LES method

- HVAC simulation for interiors

- Fatigue analysis of structures and components

- Vibrational analysis