Composite Progressive Failure Analysis

As engineers working with advanced composite materials, one of the toughest challenges we face is accurately predicting when and how our composite structures will fail. Unlike traditional homogeneous materials like metals, composites exhibit a complex, progressive failure behavior that requires specialized analysis techniques to understand.

That’s where Progressive Failure Analysis (PFA) comes into play. PFA is a powerful analytical approach that allows us to simulate the initiation and propagation of failure within a composite laminate or structure. By using stress- or strain-based failure criteria, PFA can identify the weakest points in the material and track how damage spreads, ultimately leading to the structure’s ultimate failure.

Progressive Failure Analysis Methods

The article we recently came across does an excellent job of explaining the two main methods for conducting PFA: Classical Lamination Theory (CLT) and Finite Element Analysis (FEA).

Classical Lamination Theory Based PFA

The CLT-based approach focuses on the behavior of individual plies within the laminate. It recognizes that the weaker plies oriented perpendicular to the load direction will typically fail first. As these plies lose their load-carrying capacity, the surrounding plies must compensate, leading to their eventual failure as well. This progressive ply-by-ply breakdown continues until the strongest, load-aligned plies can no longer support the increasing stresses, resulting in the laminate’s ultimate failure. you can download an Excel file for Composite Ply Calculator.

Finite Element Analysis Based PFA

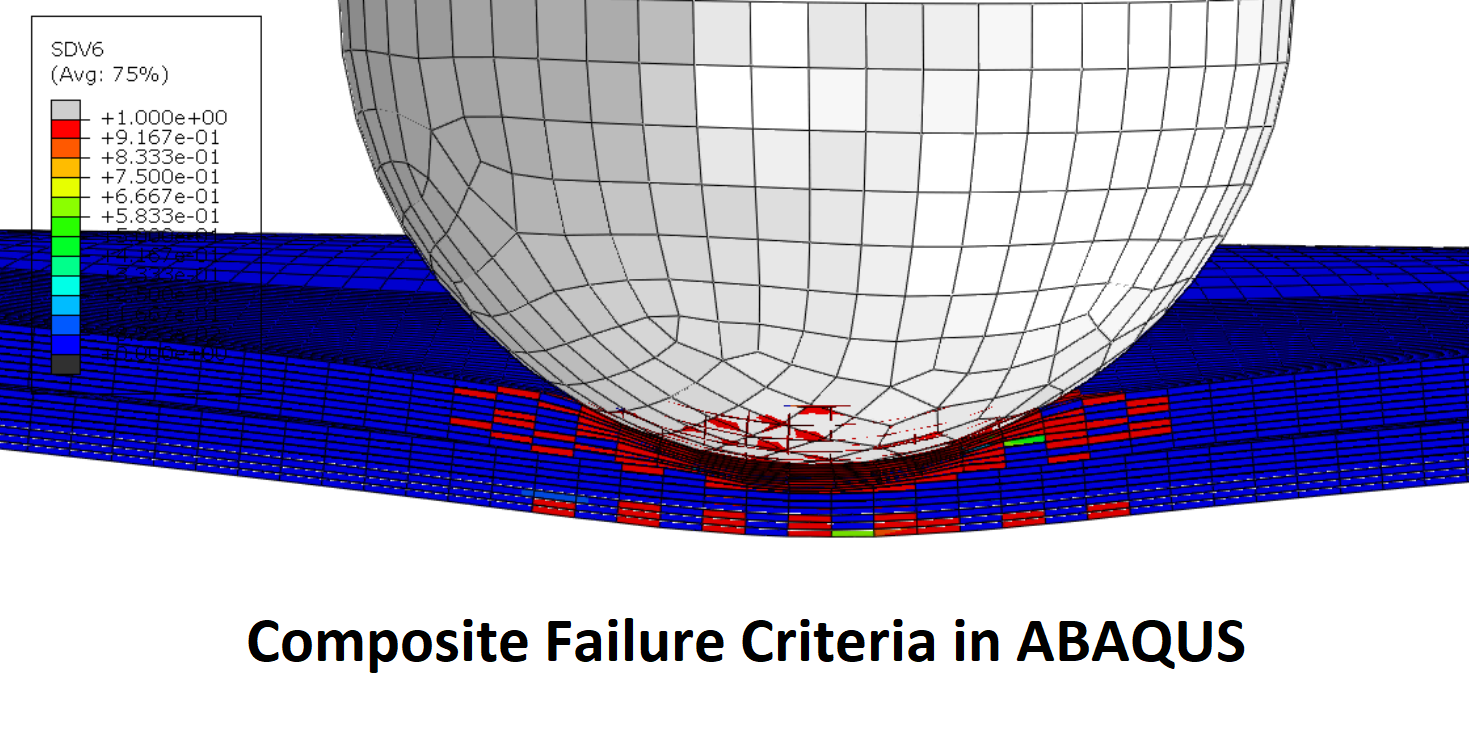

On the other hand, the FEA-based PFA method examines failure at the element level within a detailed computational model. By assigning material properties to the integration points of each finite element, the analysis can identify the first element to reach the critical failure threshold. Once that element “fails,” its stiffness is reduced, causing a redistribution of internal loads and the progressive failure of surrounding elements. This process continues until the entire structure is compromised.

A progressive failure analysis using Finite Element Analysis (FEA) can provide two important pieces of information:

How will failure initiate and propagate through the structure?

The FEA-based progressive failure analysis allows for a detailed examination of how failure initiates and spreads throughout the composite structure. By tracking the failure of individual finite elements based on stress- or strain-based failure criteria, the analysis can simulate the progressive degradation of the material as damage propagates.

This granular level of detail gives engineers valuable insights into the failure mechanisms at play, enabling them to better understand how the composite structure will behave under load and optimize the design accordingly.

What is the ultimate load that the structure can support (ultimate failure load)?

By progressively reducing the stiffness of failed elements in the FEA model, the analysis can continue to simulate the load redistribution and eventual complete failure of the overall structure. This allows engineers to determine the ultimate load that the composite component or assembly can withstand before catastrophic failure occurs.

Knowing the ultimate failure load is crucial for ensuring the safety and reliability of the composite structure, as it helps establish appropriate design margins and operational limits.

Composite Failure Analysis Software / Plugins

There are a few software packages and plugins that are commonly used for progressive failure analysis of composite materials in Abaqus and ANSYS:

For Abaqus

- Abaqus Composites Modeling Module

This module within Abaqus provides specialized features and capabilities for modeling and analyzing composite materials, including progressive failure analysis. It supports various composite failure criteria, such as Tsai-Wu, Hashin, and LaRC05, to predict the initiation and progression of damage.

- Helius PFA (by Autodesk)

Helius PFA is a plug-in for Abaqus that enables advanced progressive failure analysis of composites.

It integrates with the Abaqus workflow and provides additional failure criteria, damage modeling, and post-processing tools specific to composites.

For ANSYS

- ANSYS Composite PrepPost (ACP)

ANSYS Composite PrepPost is a comprehensive tool within the ANSYS suite for modeling and analyzing composite structures. It includes capabilities for progressive failure analysis using various failure theories, such as Tsai-Wu, Hashin, and Puck.

- ANSYS Mechanical APDL

ANSYS Mechanical APDL (Parametric Design Language) provides a scripting interface for advanced analysis, including progressive failure analysis of composites.

Users can develop custom routines and integrate them into the ANSYS Mechanical environment to conduct specialized composite failure simulations.

Additionally, some third-party plugins and add-ons may be available for both Abaqus and ANSYS to further enhance their progressive failure analysis capabilities for composites, such as:

- Digimat (by e-Xstream Engineering)

- Helius Composite (by Autodesk)

The choice of software or plugins will depend on the specific requirements of your project, the level of detail needed in the analysis, and your overall simulation workflow and preferences. It’s recommended to evaluate the features and capabilities of each option to determine the best fit for your composite analysis needs.

Conclusion

The advantage of the FEA-based approach is that it provides much more granular insight into how failure initiates and propagates through the complete structure. This allows engineers to better understand the failure mechanisms and optimize the composite design accordingly.

Whichever PFA method you choose to employ, the key takeaway is that accurately predicting composite failure requires going beyond simple first-ply failure criteria. By embracing the progressive nature of composite damage, PFA empowers us to design more reliable, lightweight, and high-performing structures that push the boundaries of what’s possible with these remarkable materials.

Would you like to learn more?

If you’d like to learn more about how our team of composite experts utilizes PFA to support our clients’ projects, please don’t hesitate to reach out. We’re always happy to share our knowledge and experience in this field.