Risk based inspection (RBI)

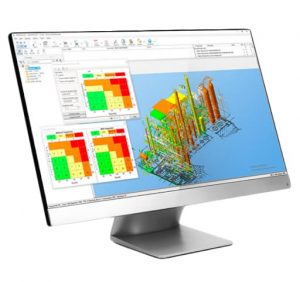

RBI ( rbi inspection )was created to meet the needs of strategic industries such as power plants, oil, gas, and petrochemicals in order to manage risk and prioritize equipment based on risk.

One of the key strategies in the oil, gas, and petrochemical industries is to maximize the operation time of facilities and the continuation of production and pay special attention to the category of safe and sustainable production. One of the methods of safe and sustainable production and increasing productivity in refinery facilities is the use of the RBI method in order to improve the effectiveness and efficiency of programs of technical inspection systems, maintenance, and active preventive maintenance (PMS).

RBI is a new method in inspection management. Risk assessment is used to plan and interpret the results of inspections, tests, and monitoring. Unlike traditional inspection methods, this method does not define a fixed time interval; Instead, for each device, a specific time interval and inspection method are determined.

RBI is a new method in inspection management. Risk assessment is used to plan and interpret the results of inspections, tests, and monitoring. Unlike traditional inspection methods, this method does not define a fixed time interval; Instead, for each device, a specific time interval and inspection method are determined.

Using RBI, while avoiding repeated inspections, rbi inspection facilities and capabilities can be focused on higher risk devices. This method is consistent with the goals and rules defined by various authorities and is also a system for prioritizing and focusing inspections on equipment that has the greatest impact on the safety and reliability of an oil, gas, and petrochemical complex. RBI inspection is used in integrated management as a key tool in improving industrial safety, efficiency, and competitiveness.

risk based inspection ( rbi inspection ) consulting

This technique is mostly performed using API 581, API 580, and ASME PCC-3-2007. Our company has the ability to synchronize FFS and RBI inspection techniques ( risk based consulting ) for different equipment. FMEA / FMECA methods are also used in preparing and compiling time schedules.

RBI Benefits

Some of the benefits of using the RBI inspection technique are:

- Classification and prioritization of equipment, units, and pipelines based on risk

- Develop an inspection plan that is financially and time-efficient

- Develop maintenance schedules that provide an acceptable level of efficiency and risk