Hydrogen Induced Cracking

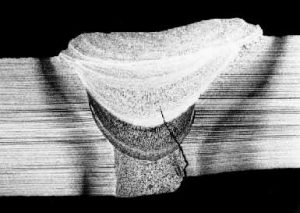

Hydrogen induced cracking (HIC) or hydrogen embrittlement is caused by the penetration of hydrogen atoms into the metal crystal lattice, often in the heat-affected zone (HAZ). The entrapment of hydrogen atoms in the material undermines the mechanical properties of the material. It also creates cavities in the metal that reduce its flexibility and tensile strength and can lead to cracking and eventually fracture.

Metal materials play a key role in the manufacture of industrial components and equipment due to specific mechanical properties such as strength, stiffness, toughness, and high-temperature resistance. But for more than 100 years, the effect of hydrogen has been proven to dramatically reduce the fracture toughness of advanced alloys (it has been seen in modern steels that crack growth is expected to be one-tenth of the fracture toughness).

HIC in Industry

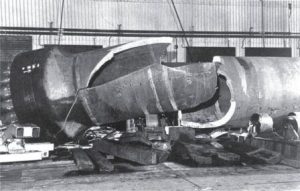

Industries that involve the use of hydrogen or hydrogen-containing substances are most susceptible to hydrogen-induced cracking. Some examples of such industries include oil and gas, chemical processing, and petrochemicals. HIC can occur in pipelines, storage tanks, and other equipment that come into contact with hydrogen, causing significant damage and safety risks. Therefore, it is important for these industries to take preventive measures such as selecting appropriate materials, implementing proper maintenance procedures, and conducting regular inspections to minimize the risk of HIC.

Hydrogen Induced Cracking is found in plain carbon steels and low-strength alloy steels, with other names such as Cold Cracking, Toe Cracking, and Under Bead cracking is also known. Indicates the different naming of the crack location and its timing (which can occur up to 72 hours after welding).

Pressure vessels serving acidic environments (especially in refineries) can be at risk of hydrogen cracking due to the introduction of hydrogen into the material. The risk associated with the specific working conditions and quality of the steel used in the construction of the pressure tank must be properly managed to ensure maximum safety with minimum cost.

Nowadays, the usual management strategy is based on Risk-Based Inspection or RBI, which defines a specific inspection plan followed by the Fitness-for-Service (FFS) method, the ability to continue equipping the service using methods such as failure mechanics inspection.

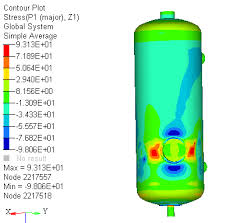

Finite Element Analysis of HIC

Hydrogen-induced cracking finite element analysis (FEA) is a method used to simulate and analyze the behavior of materials under the influence of hydrogen. Several methods are commonly employed in HIC FEA analysis to study the phenomenon and its effects. Here are some of the different methods used:

- Hydrogen Diffusion Analysis: This method focuses on studying the diffusion of hydrogen within the material. It helps in understanding how hydrogen atoms migrate through the material and accumulate at specific locations, leading to cracking.

- Stress Analysis: Stress analysis is crucial in HIC FEA as it helps evaluate the stress distribution within the material. By considering the interaction between hydrogen atoms and stress fields, this method aids in identifying areas of high stress concentration where hydrogen-induced cracking is likely to occur.

- Strain Analysis: Strain analysis involves studying the deformation or strain distribution within the material. It helps in understanding how hydrogen-induced cracking affects the material’s mechanical properties and behavior.

- Fracture Mechanics Analysis: This method focuses on evaluating the crack growth and propagation under the influence of hydrogen. It involves studying parameters such as stress intensity factor, crack tip opening displacement, and fracture toughness to assess the material’s resistance to cracking.

- Material Characterization: Material characterization techniques are used to gather data on the material’s properties relevant to HIC FEA analysis. This includes information on hydrogen diffusion coefficients, mechanical properties, hydrogen solubility, and other relevant parameters.

BanuMusa R&D Capabilities:

- Modeling HIC in hydrogen transport equipment

- Failure & fatigue damage analysis

- Modeling of fatigue corrosion

- Simulation of crack growth due to hydrogen diffusion

- Prediction of equipment life

- Simulation of welding and prediction of residual stress

- Fitness for service assessments (Levels 2 & 3)

BanuMusa R&D Services:

- Developing user subroutines (UMAT/UEL/UMATHT/USDFLD/UELMAT ) in Abaqus

- Phase field modeling of hydrogen embrittlement

- Cohesive zone modelling of hydrogen induced cracking

- Hydrogen-assisted stress corrosion cracking simulation

- Computational modeling of hydrogen-assisted fatigue crack

- Stress corrosion cracking (SCC) using phase field method

- Coupled hydrogen diffusion with mechanical deformation

- Level 2/3 FFS based on API 579 using Abaqus FEA and Signal FFS