Metal Forming with Abaqus

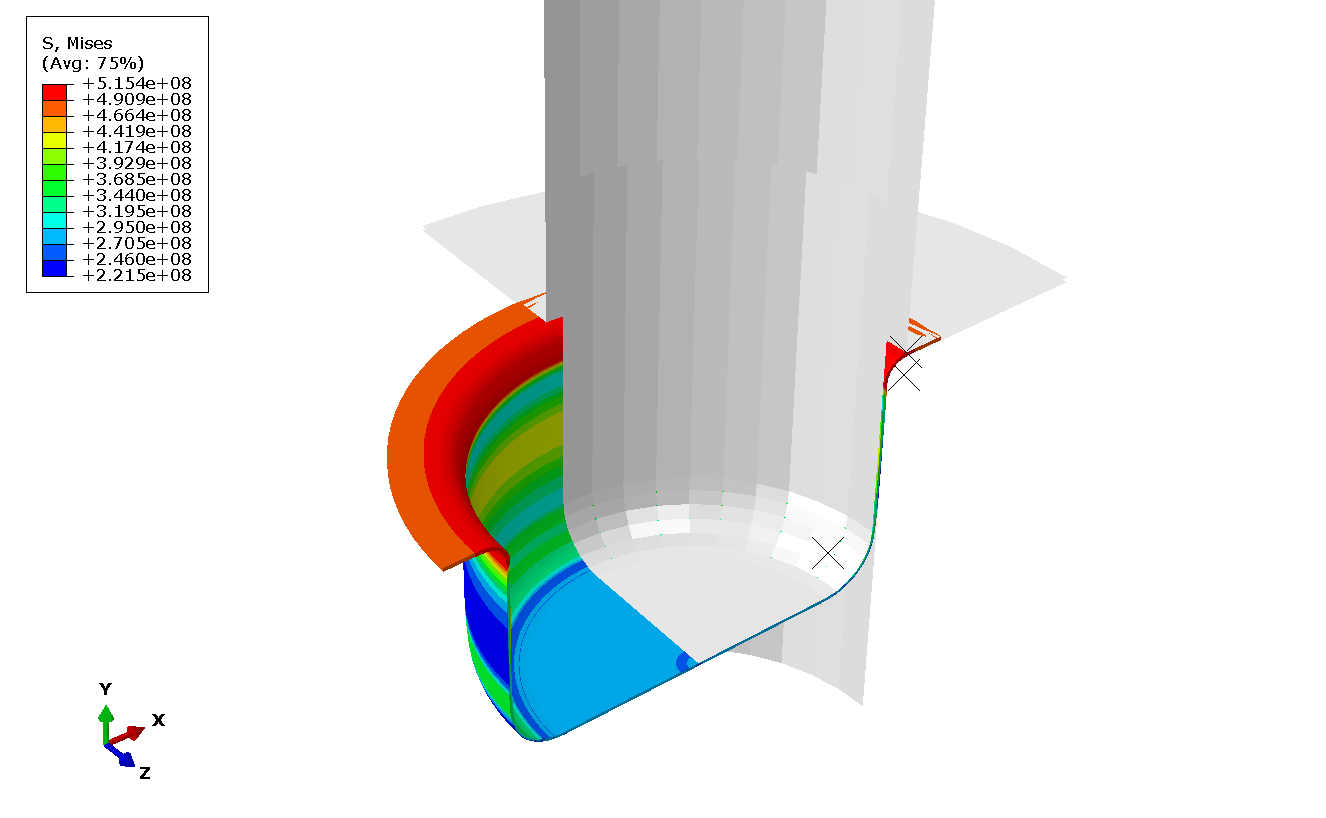

Simulating metal forming processes numerically can be challenging due to geometric, material, and contact nonlinearities. However, despite the difficulties, there are advantages to using numerical simulations in forming processes. These simulations can help identify potential forming problems before tooling fabrication, reducing both the cost and length of product development cycles. They can also improve the quality of manufactured parts by testing for spring back and stretching, ultimately reducing the time and cost associated with tooling rework.

This course is structured with lectures, demonstrations, and workshops. The workshops are crucial for the training as they aim to solidify the ideas covered in the lectures and demonstrations. Their purpose is to give participants hands-on experience in conducting and troubleshooting real engineering problems.

What you’ll learn

In Metal Forming with Abaqus, you will learn about solution procedures, ALE adaptive meshing, model change, and modeling quasi-static processes. This course typically covers finite element analysis (FEA), material models, material data calibration, and verification and validation (V&V) within Abaqus.

Upon successfully finishing this course, every participant will have the ability to:

- Basics of metal forming processes simulation

- Modeling techniques for metal forming

- Techniques for modeling tool geometries, workpiece materials, and boundary conditions in Abaqus

- Prediction of defects like wrinkling, tearing, and springback

- Hands-on examples and exercises demonstrating the use of Abaqus for various metal forming processes, including sheet metal stamping, extrusion, hydroforming, rolling analysis, multi-pass rolling, drawbead modeling, superelastic forming and forging

Overview of the course

Lecture 1 Overview

- Understanding of Metal Forming Processes:

- Objectives of metal forming simulation

- Overview of common metal forming techniques like stamping, extrusion, rolling, and forging.

- Fundamental principles and mechanics of metal deformation during forming operations.

- Abaqus solvers for metal forming simulation

Lecture 2 Hydroforming

- Workshop: Hydroforming of fiber metal laminate (FML) plate

Lecture 3 Rolling Forming

- Workshop: Cold rolling simulation

- Workshop: Coupled thermo-mechanical simulation of multi-step (9) hot rolling

Lecture 4 Forging

- Workshop: Modeling of closed-die forging

Lecture 5 Drawing

- Workshop: Wire Drawing

- Workshop: Bulk Forming of a Cup

Lecture 6 Equal Channel Angular Pressing

- Workshop: Equal Channel Angular Pressing (ECAP) process simulation

Lecture 7: Spinning Forming

- Workshop: Cone Spinning Forming simulation with Abaqus

– Appendixes

- Introduction to useful tools, plugins, and datasets for metal forming simulation

Knowledge Prerequisites

Metal Forming with Abaqus course is suggested for engineers who have familiarity with Abaqus.

Who should take this course?

Those engaged in the modeling and simulation of metal forming using Abaqus. However, possessing an Engineering degree or prior work experience in the field is not mandatory.

This course is available offline with 24/7 online support.

A certificate of completion will be provided to participants who successfully attend and finish the course.

All the files including videos, workshops, and lecture notes can be downloaded on your personal computer. Therefore, you can watch this training, practice, and also communicate with the mentor online at any time and anywhere.

Targeted Audience

- Mechanical Engineers

- Simulation Analysts

- Abaqus Application Engineers

- Abaqus Users

- Safety, Reliability, and Quality Engineers

- CAE and FEA engineers

- Design engineers

- Anyone who wants to learn Abaqus and engineering simulation

Available Releases

2024

Duration

5 hours

Discipline

This metal forming simulation with Abaqus course is designed to cover the utilization of Abaqus for FE analysis of metal forming. It is aimed at engineers involved in FEA simulation who wish to enhance their comprehension of the intricate mechanical and failure behavior associated with metal forming.

Virtual Mentoring Platform:

Skype+AnyDesk is BanuMusa’s interactive online mentoring solution with the most reliable features to help you before, during, and after your sessions. it is a robust training platform that engages students/attendees virtually.

Cancellation Policy:

A full refund is available for cancellations more than 30 days before the course recording start date. Within 30 days of the course start date, course credit can be transferred to another attendee within the same company, or can be kept on file to be applied to a future BanuMusa training course.

Need help? Get a consultation from our experts.

Telegram: +98-915-55-20-388

WhatsApp: +98-915-55-20-388

Find Us on WeChat

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at  After the end of the course, a Certificate of Completion will be awarded to you by BanuMusa R&D.

After the end of the course, a Certificate of Completion will be awarded to you by BanuMusa R&D.

Reviews

There are no reviews yet.