View Large

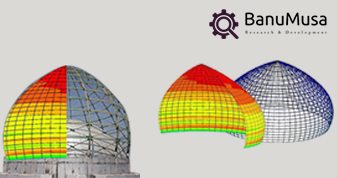

View LargeNumerical Modeling of Biodegradable Stent Corrosion

Numerical modeling of biodegradable stent corrosion is important because it allows researchers and engineers to simulate and predict the behavior of these stents over time. By using numerical models, they can study how biodegradable stents degrade in the body due to corrosion processes. This modeling helps in understanding the degradation rate, the release of degradation by-products, and the impact on the surrounding tissues. Ultimately, this information is crucial for designing more effective and safe stents for medical applications.

Heart, Stents, and Biodegradable Materials!

One of the most common diseases in today’s human societies is obstruction of the coronary arteries of the heart in old age, which disrupts the normal flow of blood to the organs of the body, in cases such as the coronary arteries of the heart, which are responsible for supplying blood to the heart muscle. It can turn into a dangerous issue that can eventually lead to a heart attack.

Biodegradable Stent Simulation

One of the new ways to treat this complication and open the vital arteries is to use a device called Stent. Biodegradable materials are materials that can be decomposed naturally or by environmental activities and can be used in the production of various materials such as paper, plastic, etc. One of the applications of biodegradable materials is their use in the production of stents, one of the advantages of which is the gradual disappearance of the stent after a certain time in the body.

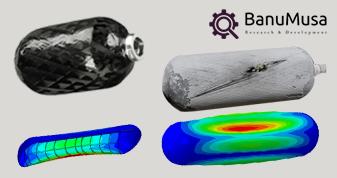

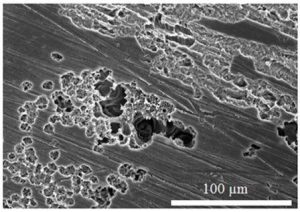

Biodegradable stent corrosion test

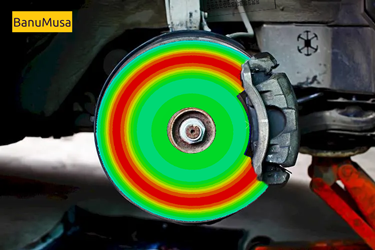

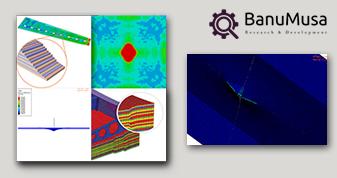

Stent Corrosion Simulation Using Abaqus

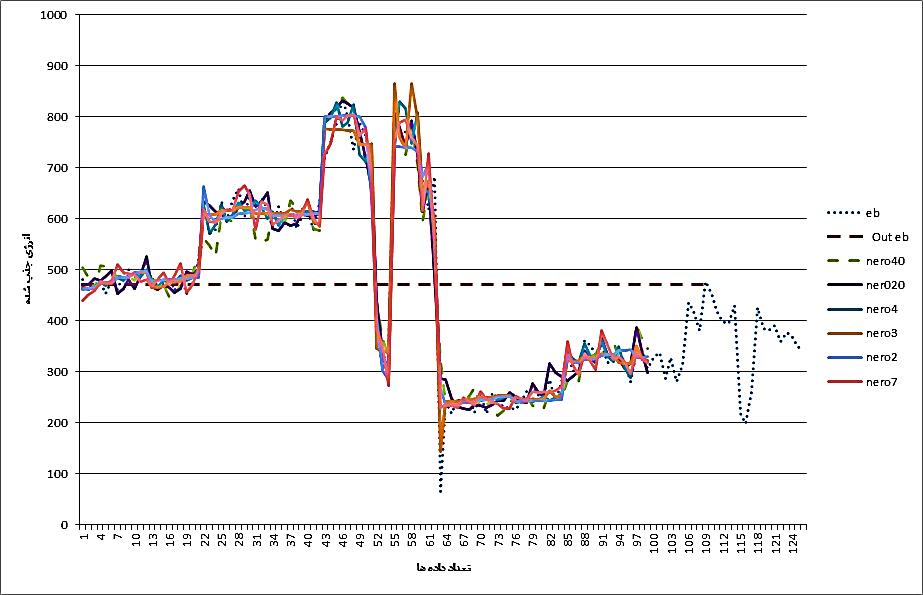

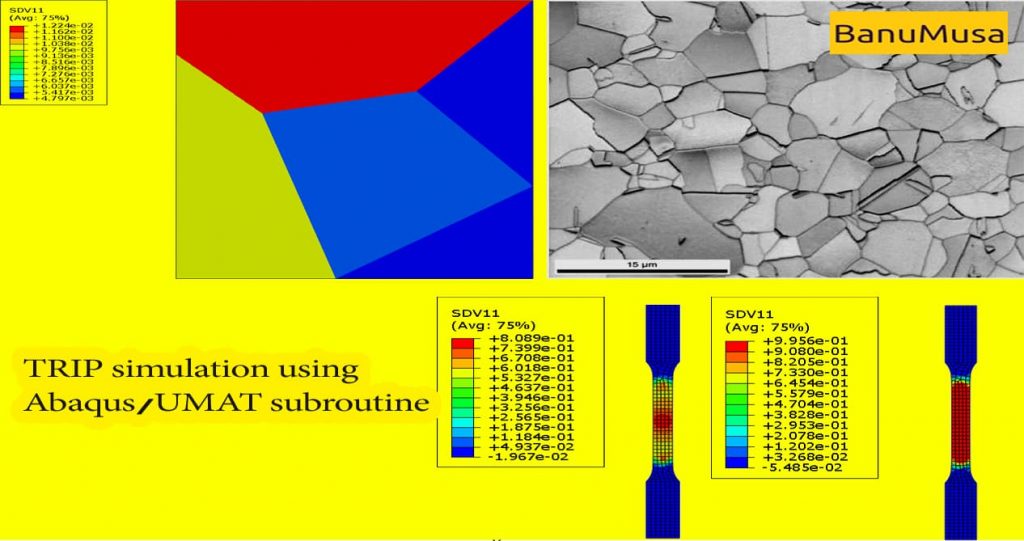

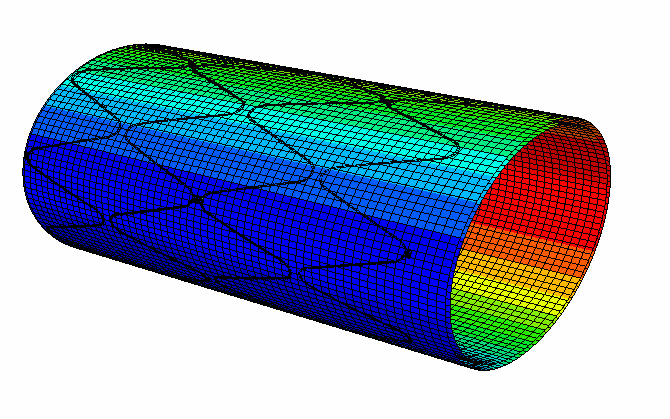

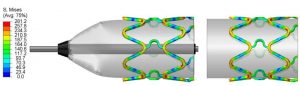

One of the effective factors in the success of stent use is the correct analysis of its mechanical behavior. In this project, a biodegradable stent sample containing reliable laboratory test data was selected by studying the existing designs. Then its mechanical behavior was investigated using the finite element analysis (FEA) method. For this purpose, first, the stent corrosion failure model with a specific material was determined and then this model was used for coding in the UMAT subroutine of Abaqus for a specimen. The results of the numerical modeling of stent corrosion were compared with the laboratory test results of the same model.

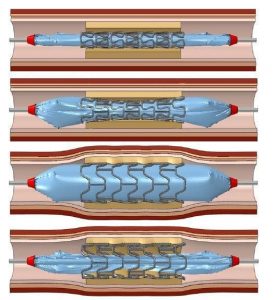

The adaptation of the results was very good. The artery was then modeled and a stent was placed. In this way, the mechanical behavior of the stent was thoroughly studied and evaluated. The performance of this stent was simulated in very close to real conditions and its results were delivered to the employer to continue the research and development (R&D) and laboratory samples.

Stent and balloon simulated in Abaqus

Biodegradable stent corrosion modeling achievements

- Determining the corrosion model for the material used to manufacture the stent

- Writing of the UMAT subroutine predicts random and uniform corrosion in stents

- Generate Python script in Abaqus to map basic corrosion data

- Comparison of the results of numerical modeling of stent corrosion for laboratory specimens with experimental results

- Modeling a part of the artery completely

- Stent placement in an artery

- Investigation of complete mechanical behavior of stents

- Next: performance optimization

Contact us for consulting and communication with an expert about the stent numerical simulation.

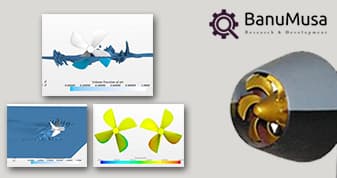

Abaqus FEA simulation of Stent

The Living Heart Project

The SIMULIA Living Heart Human Project offers a distinctive testing platform that allows for the virtual deployment of a stent within coronary arteries, which can then be mechanically deformed throughout the cardiac cycle. By analyzing the mechanical deformation outcomes, researchers can evaluate the long-term durability of the stent. This virtual testing environment provides a methodologically precise and physiologically accurate way to assess the performance of both new and established medical devices, all without subjecting patients to any unnecessary risks.

Recent Papers