View Large

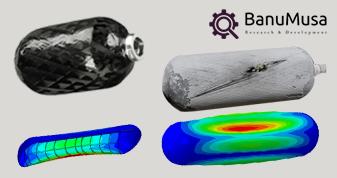

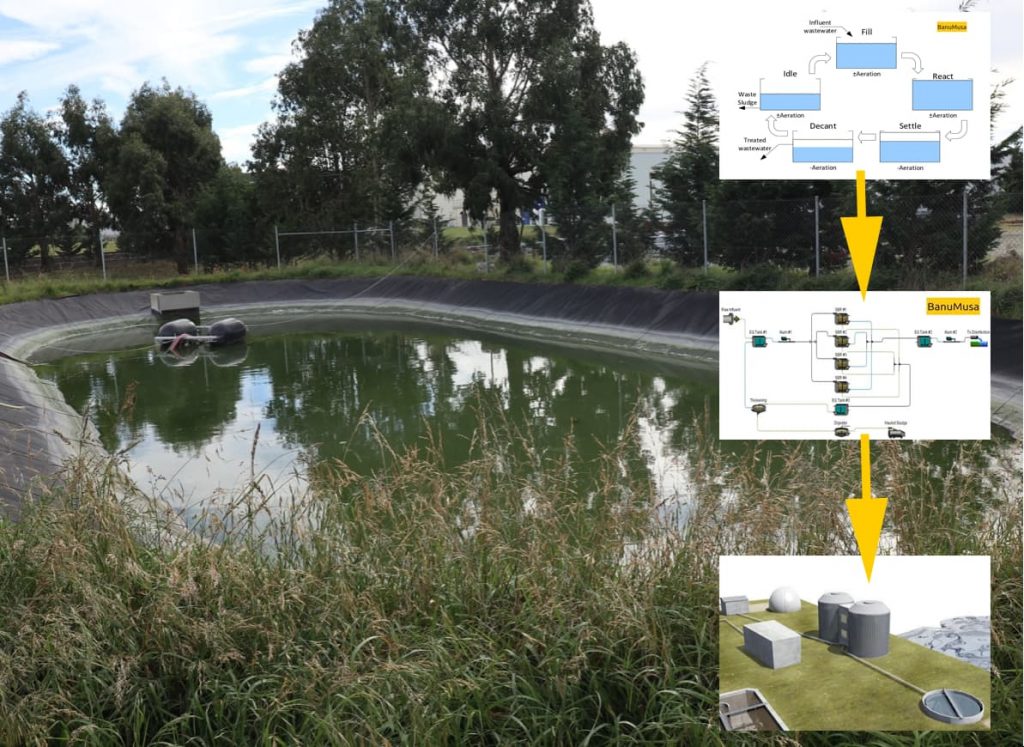

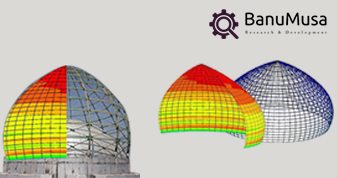

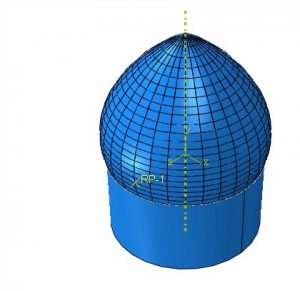

View LargeDesign and manufacture of composite structural dome

Design and manufacture of composite dome

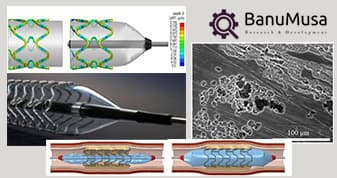

The advantages and disadvantages of using composite materials and materials are described in detail here.

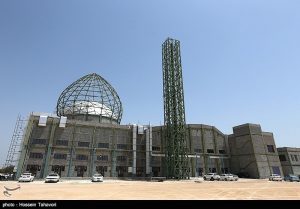

This post is just an example of the work done by Benomousi Company in the construction of composite structural domes. It should be noted that the dome of the designed composite structure is the largest composite dome of the region and the Middle East.

In this project, design, simulation and technical calculations of the dome of Mosalla Kish composite structure were performed.

Due to the limitations of this project (limitations such as structural load, large dimensions of the structure, ambient humidity and reduced service life of common materials, the regional importance of Mosalla Kish, the safety of clients and worshipers, the possibility of using common materials in construction There was no dome (metal and brick dome) and this design and calculations were done.

You can visit this link to check the failure criteria of composite material

Objectives of the composite dome structure design project

Design composite dome | BanuMusa Co.

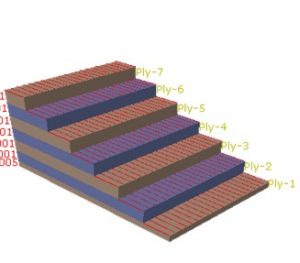

- Determine the appropriate porcelain layer of the composite

- Determining the type of fibers and resin

- Determining the strength of the structure

- Determining the optimal weight

- Connection design and analysis

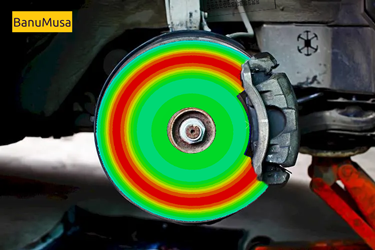

- Temperature analysis

- Creep and fatigue analysis

- Impact load analysis

- Shipping and installation analysis

- Determining the optimal size of composite panels

- Determining methods to strengthen the structure

- Determination of standard rise and strain

- Determining the adhesion resistance of tiles and composites

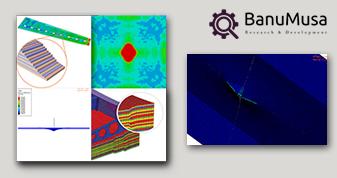

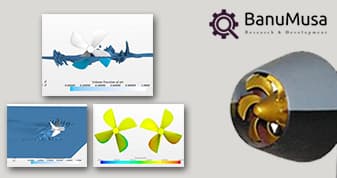

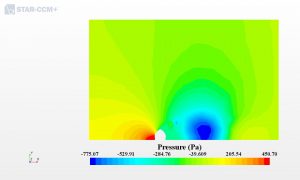

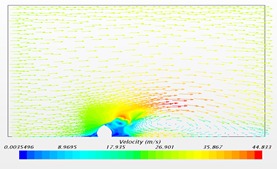

- Wind tunnel simulation and comparison of results with standard calculations and regulations

- Moisture analysis of composite structures and tiles

- Determine the appropriate thickness and data required for construction

Design composite dome 1 | BanuMusa Co.

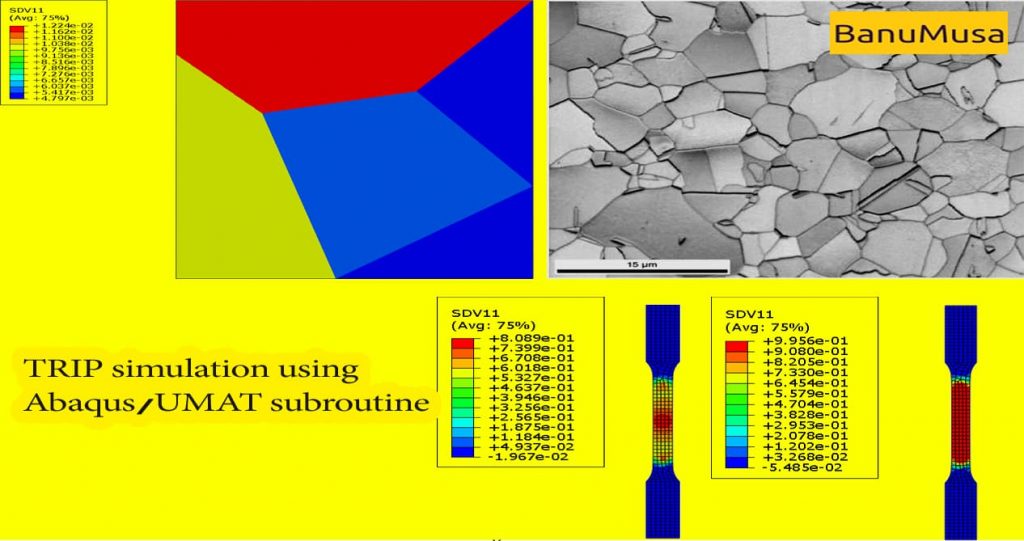

Although composite materials have been used in the construction of various domes in Islamic and non-Islamic structures for about 20 years, but there are many ambiguities in its exact design. Therefore, the use of numerical simulation method along with the tests performed, in addition to increasing the reliability of the structure, also reduces construction costs.

Analysis of the dome composite structure includes the study of the structure’s resistance to:

- Dead load: includes the weight load of the structure

- Live load: includes wind, snow and rain, earthquake and traffic

Loads applied to the composite dome structure:

Design composite dome 2 | BanuMusa Co.

- Dead weight

- Snow load

- Load the wind

- Traffic times

- Earthquake load

Standards used:

- National Building Regulations – Topic Six

- 2800 Earthquake Design Code

- ASCE7-16 Standard

- EN 1990

- European Commission

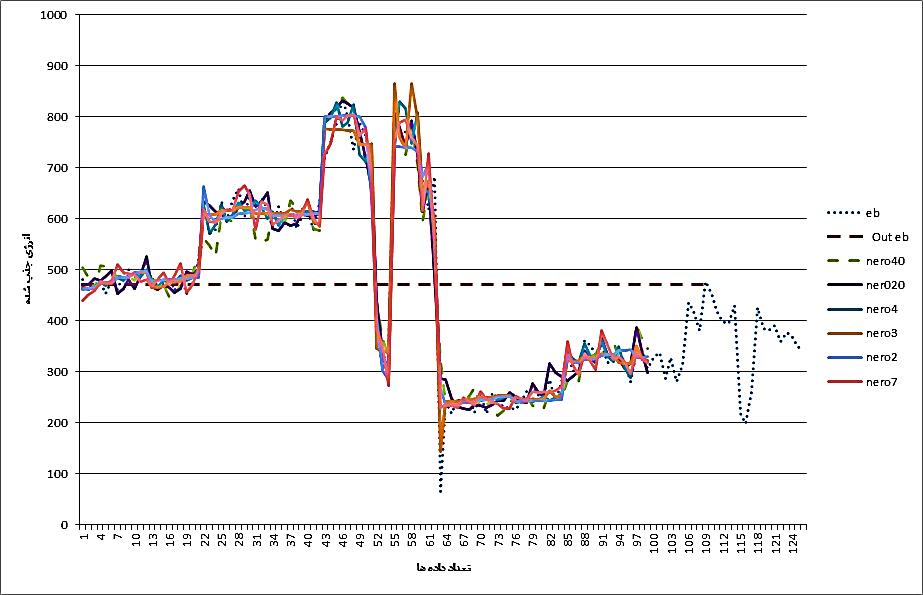

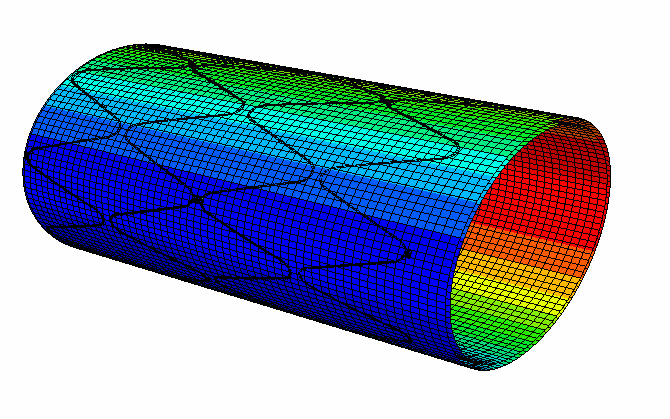

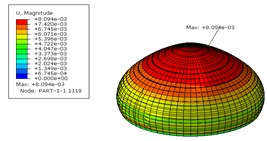

Results of composite dome structural analysis:

Design composite dome 3 | BanuMusa Co.

In this analysis, the data used and the results obtained were validated and validated with experimental and standard results.

In order to analyze the earthquake, the standard 2800 fourth edition was used.

Modal analysis of the dome structure was performed to determine the natural frequencies.

Methods used for calculations and analysis of composite dome structures:

Design composite dome 4 | BanuMusa Co.

- Finite Element Method (FEM)

- CFD method

- experimental method

- manual calculations

Thanks to calculations and simulations, the cost of design and construction of this composite dome structure was reduced by about 30%. This cost reduction is due to the following.

- Reduce laboratory tests to determine the properties of composite materials

- Reduce material waste and common trial errors and errors

- Determining the optimal thickness of the composite and thus reducing the material consumption in construction

- Design of cost-effective connections to similar examples

Contact us for advice on designing, calculating and constructing a dome of a composite structure.

Design composite dome 5| BanuMusa Co.