View Large

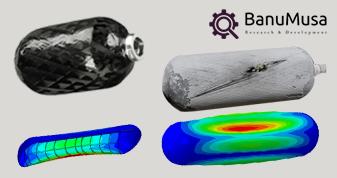

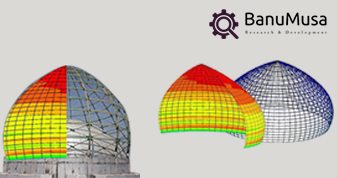

View LargeImpact Simulation of Composite Pressure Vessels

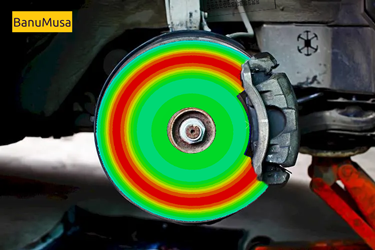

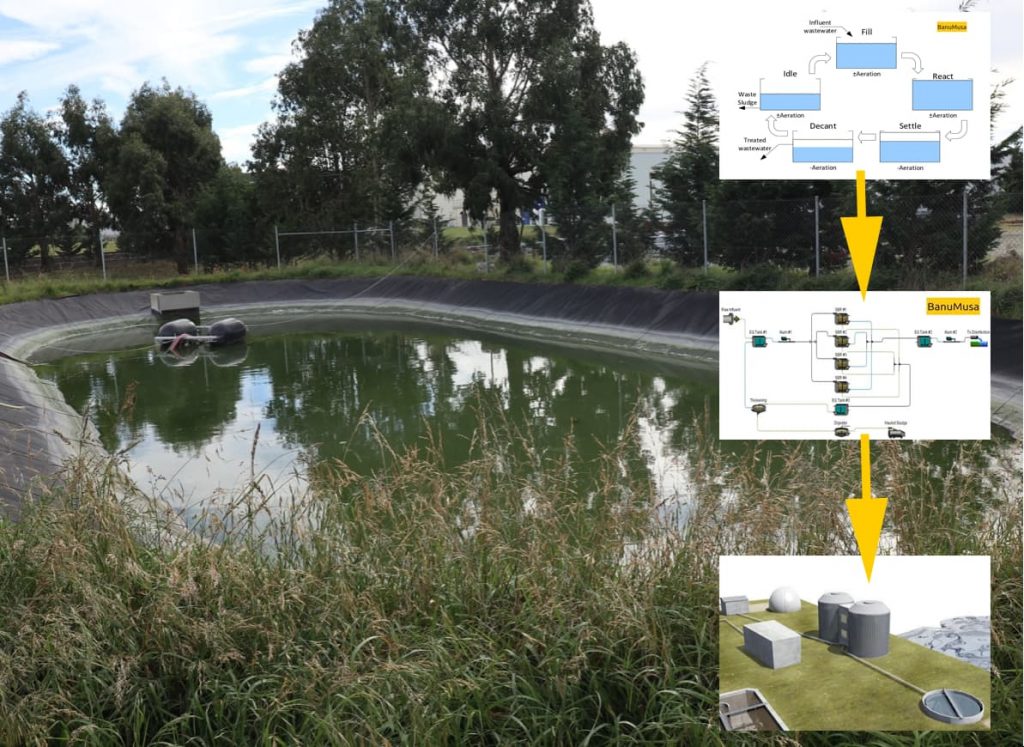

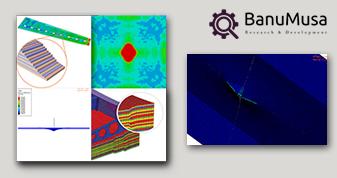

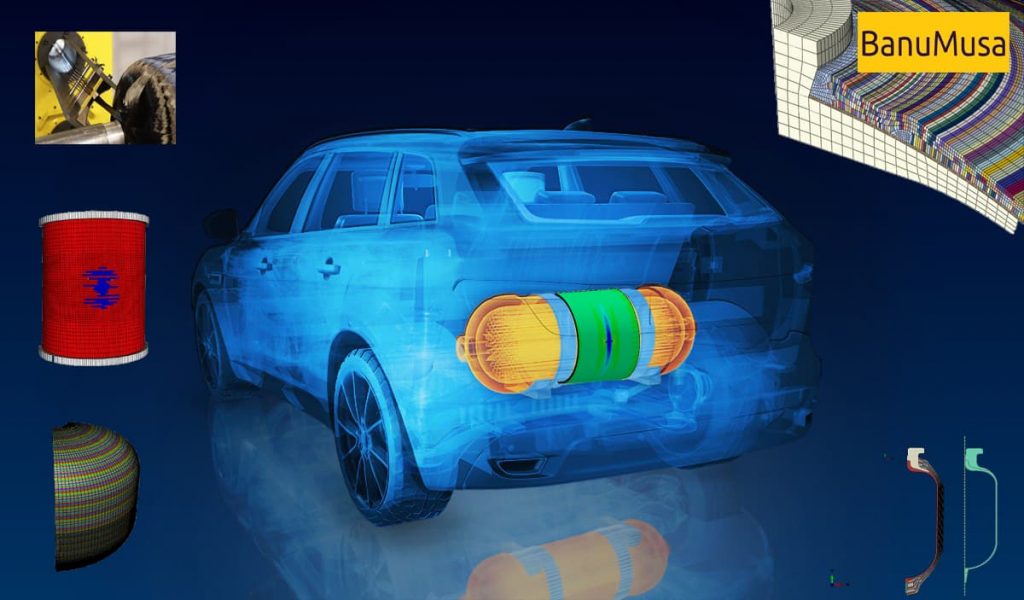

Impact simulation of composite pressure vessels: One of the disadvantages of composite materials is their weakness against impact loads. It is important to study the impact of impact on composite pressure vessels due to their sensitive conditions in various industries such as marine, aerospace, and automotive industries.

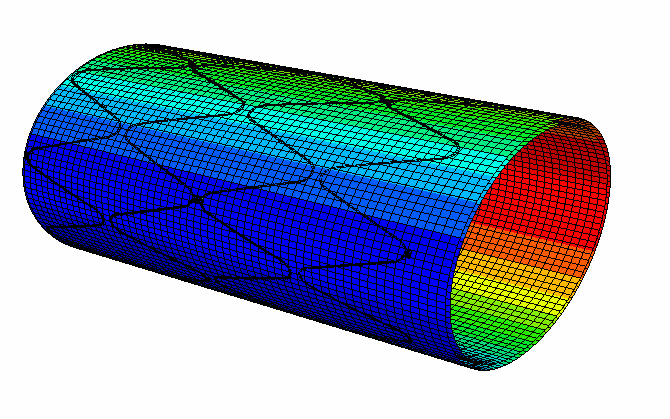

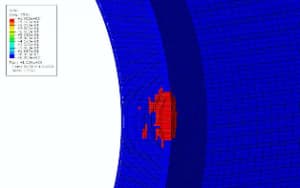

Impact Simulation of composite pressure vessels – delamination damage

Finite Element Impact Analysis of Composite Pressure Vessels

Finally, a composite pressure vessel was subjected to impact loading according to ASME X in Abaqus finite element software and damage evolution was investigated; The amount of residual compressive strength under impact loading was then investigated. The results of this study showed that low-velocity impact damage reduces the residual strength of composite pressure vessels by 30 to 60%.

The design of the pressure vessel, impact simulation, and damage assessment in engineering software such as Abaqus and Ansys require the expertise that our engineers in the BanuMusa R&D company have the necessary expertise in this field.

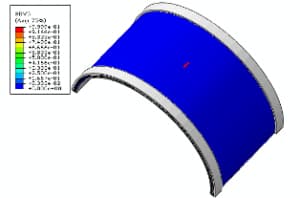

Finite Element Impact Analysis of Composite Pressure Vessels – Type IV

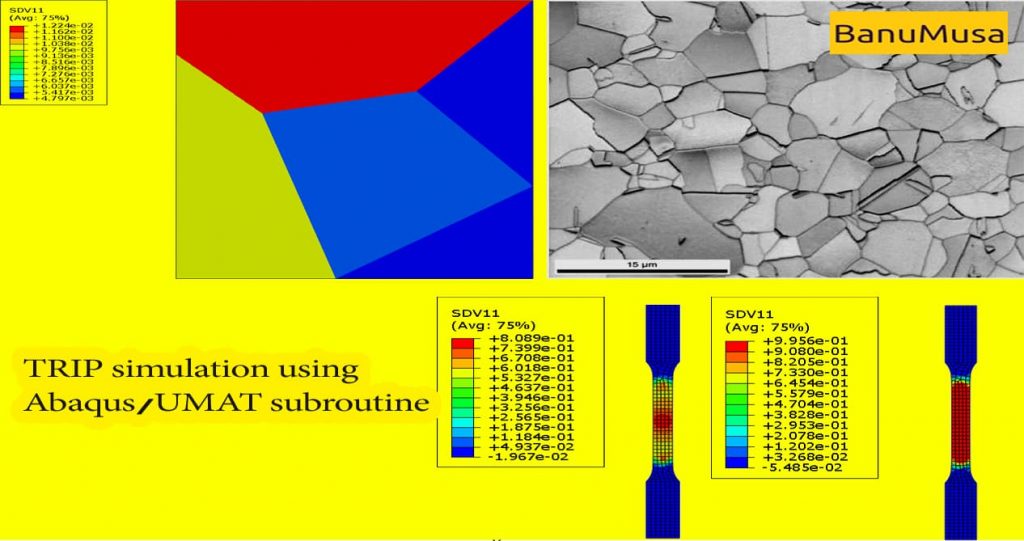

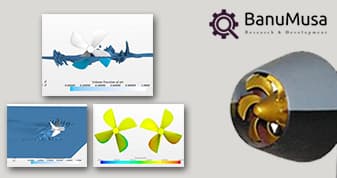

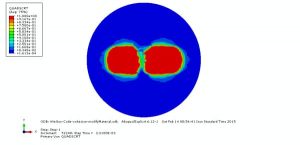

Impact Simulation of Composite Pressure Vessels using 3D Hashin VUMAT Subroutine

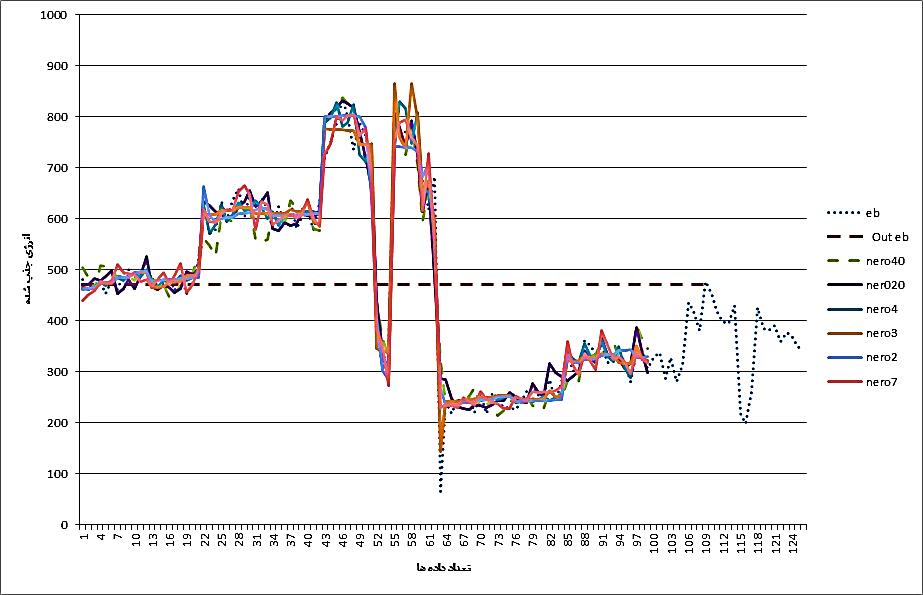

Impacts on FRP composite materials cause damage to them. These damages are not visible to the naked eye and can reduce the strength of the material by up to 60%. In Abaqus software for shell elements, the Hashin damage material model can be used to simulate the progressive failure of composite materials; But this is not possible for three-dimensional solid elements. Therefore, in the present project, a progressive failure VUMAT subroutine based on continuous damage mechanics (CDM) and smeared cracking method has been written to predict damage. 3D Hashin VUMAT subroutine can show the damage modes separately. In the 3D Hashin VUMAT subroutine, Hashin three-dimensional criterion and maximum stress criterion are used to evaluate the onset of damage and identify damage modes.

3D Hashin VUMAT Subroutine for 3D COPVs – Matrix cracking & fiber fracture

3D Hashin VUMAT Subroutine for Abaqus with Exponential Damage Evolution

Composite Pressure Vessel Design and Simulation

There are various software and computational tools for composite pressure vessel design and simulation. The reason for the complexity of designing and simulating composite pressure vessels is the use of filament winding methods in their production. Some of the tools used to design and simulate composite pressure vessels are as follows:

More information about composite pressure vessel design and simulation tools.

if you are interested in any of these tools, contact us for more information.

Why Finite Element Impact Analysis of Composite Pressure Vessels Matters

There are a few reasons why finite element impact analysis of composite pressure vessels matters:

- Safety – Composite pressure vessels are used to store flammable, explosive or toxic gases and liquids. Ensuring they can withstand impact loads without failing is critical for safety. FE impact analysis helps verify this.

- Performance – Composite pressure vessels are designed to have a long service life under cyclic loads and impact events. FE impact analysis helps optimize designs to achieve the required performance.

- Cost – Physical impact testing of actual vessels is expensive and destructive. FE impact simulations provide a cost-effective way to evaluate design variants and qualification requirements.

- Design Optimization – FE impact analysis results provide insights into how impact loads cause damage, stresses and failure. This helps engineers modify vessel designs to improve impact resistance.

- Failure Prediction – FE impact simulations can determine the impact energy, velocity or force that will cause failure of a given vessel design. This helps establish impact requirements for qualification testing.

- Damage Prediction – FE impact analysis can accurately predict the initiation and progression of damage modes like delamination and fiber breakage. This indicates the robustness of a design.

- Weight Reduction – Composites enable lighter vessel designs, but the laminate must be optimized for impact loads. FE impact simulations help establish the minimum ply schedule and thicknesses required.

- Insights – FE impact simulations provide insights into impact-induced failure mechanisms that are difficult to observe during physical testing. This improves understanding.

- Validation Tool – FE impact simulations can be validated against physical impact tests to improve model accuracy. Then they act as a virtual testing tool.

So in summary, finite element impact analysis of composite pressure vessels matters because it helps improve the safety, performance, cost, weight, and failure prediction capabilities of these vessels by providing insights into damage mechanisms, failure loads, and optimal laminate designs. All of this helps engineers qualify and certify vessels for use within impact load requirements.