Additive Manufacturing Simulation with Abaqus

Additive Manufacturing Simulation with Abaqus course introduces you to the latest modeling methods of additive manufacturing or 3D printing of metals and polymers. In addition, it introduces you to the plug-in for additive manufacturing modeling and subroutines that have been added specifically from Abaqus 2017 onwards, and almost everything you need to know. Also, a chapter is specially designed for welding modeling in Abaqus in this unique training package. During the training, you communicate with the expert online and ask any questions and doubts you may have.

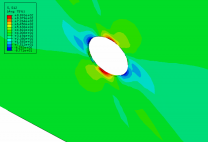

Abaqus can be used to simulate the deposition of material layer by layer, as well as the resulting thermal and mechanical effects. This allows engineers to predict and optimize the properties of additively manufactured parts, such as their strength, durability, and dimensional accuracy.

Introduction to Additive Manufacturing

Additive Manufacturing (AM), commonly known as 3D Printing, is indeed the process of creating 3D objects by adding material layer by layer. It’s a technology that allows for the production of functional parts directly, rather than just prototypes, making it a versatile and innovative manufacturing method.

AM Modeler Plugin

The additive manufacturing plug-in provides an extensive and adaptable software solution that reduces the chances of errors while simulating the additive manufacturing process in Abaqus. This tool enhances efficiency and accuracy in modeling additive manufacturing processes. From Abaqus 2022 onwards, this plugin will be installed during software installation.

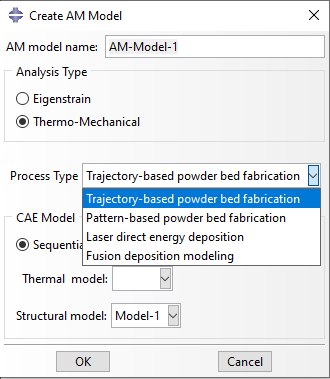

In AM Modeler You need to select the type of analysis and process based on the specific additive manufacturing process you wish to simulate. There are two analysis types to consider: eigenstrain and thermomechanical.

For eigenstrain analysis, you have the option to choose between trajectory-based or pattern-based process types.

In thermomechanical analysis, you can select from four process types:

- Trajectory-based powder bed fabrication

- Pattern-based powder bed fabrication

- Laser direct energy deposition

- Fusion deposition modeling

What you’ll learn

What you’ll learn

In Additive Manufacturing Simulation with Abaqus, you will learn about 3D Printing Simulation in Abaqus, ways to model, and verification.

Upon completion of this course, you will be able to:

- Use Abaqus/Standard to simulate the 4 different AM Processes:

- Powder Bed

- Polymer Extrusion

- Direct Energy Deposition

- Welding

- Use Abaqus/CAE AM Modeler plugin to set up the modeling process

- Understand the new data structures and user subroutines in Abaqus

- Write user subroutines to customize the application for specific process

- Postprocessing and visualization of the results

Overview of the course

Lecture 1 Introduction to AM Process Simulations

- Introduction to Additive Manufacturing

- Motivation for AM Process Simulation

- Process Simulation Overview

Lecture 2 New Data Structures in Abaqus

- Introduction

- Data Structures

- Table Collections

Lecture 3 Modeling Powder Bed Method

- Introduction

- Process specific details for AM

- Powder Bed Method

- Workshop 1: Sequential thermomechanical analysis of a laser powder bed fusion build

Lecture 4 Polymer Extrusion Simulations

- Introduction

- Process-Specific Details of Polymer Extrusion

- Polymer Extrusion Process Simulation

- Modeling Highlights

- Event Series Input Type for Polymer Extrusion

- Parameter Table Type for Polymer Extrusion

- Element Activation for Polymer Extrusion

- Cooling

Lecture 5 Process-Specific Details of Welding

- Introduction

- Abaqus Welding Interface (AWI) Plugin

- Process-Specific Details of Welding

- Modeling Highlights

- Algorithm Details

- Parameter and Property Tables

- Table Collection for Welding

- Element Activation Process for Welding

- Activation Algorithm Details

- Element Heating for Welding

- Heating Algorithm Details

- Cooling

Lecture 6 User Subroutines Overview

- Overview of Some User Subroutines

- Where User Subroutines Fit into Abaqus/Standard

- Including User Subroutines in a Model

- Writing Output from User Subroutines

- Compiling and Linking User Subroutines

- Debugging and Recommended Programming Techniques

Lecture 7 AM Process Subroutines

- Overview of Some User Subroutines

- UEPActivationSetup – for setting up data needed (from MInT) for Element Activation and Evolving free surface (using *Element Activation and Film/Rad FFS/RFS)

- UMDFLUXSetup – for setting up data needed (from MInT) for moving flux in the UMDFLUX user subroutine

- UEPActivationVol() – to obtain volume fraction increase for element activation

- UMDFLUX() – Usub to prescribe multiple moving heat fluxes

- UMATHT – heat transfer analysis

- DFLUX – Model heat source

- UEXPAN/UMAT – Handle thermal strains

- UHARD, USDFLD

Lecture 8 AM Modeler Plug-in

- Model Change vs. New AM Method

- Workshop 2: Laser Direct Energy Deposition – Curlbar

- Workshop 3: Sequential thermomechanical analysis of a directed energy deposition build

Knowledge Prerequisites

Additive Manufacturing Simulation with Abaqus is recommended for engineers with experience using Abaqus.

Targeted Audience

Simulation Analysts

Available Releases

Abaqus 2024, Abaqus 2023, Abaqus 2022, Abaqus 2021, Abaqus 2020, Abaqus 2019, Abaqus 2018, Abaqus 2017, Abaqus 2016, Abaqus V6.14, Abaqus V6.13, Abaqus V6.12

Duration

5 hours

Discipline

Advanced Abaqus

Additive Manufacturing Simulation with Abaqus is designed to cover the utilization of the Abaqus AM Modeler plugin, special user subroutines, and valuable techniques for modeling additive manufacturing in Abaqus. However, the course material can also be valuable for modeling various other types of analysis such as welding. It is aimed at engineers who are involved in additive manufacturing simulation and wish to enhance their comprehension of the intricate mechanical behavior associated with complex material models.

Virtual Mentoring Platform:

Skype+AnyDesk is BanuMusa’s interactive online mentoring solution with the most reliable features to help you before, during, and after your sessions. it is a robust training platform that engages students/attendees virtually.

Cancellation Policy:

A full refund is available for cancellations more than 30 days before the course recording start date. Within 30 days of the course start date, course credit can be transferred to another attendee within the same company, or can be kept on file to be applied to a future BanuMusa training course.

Need help? Get a consultation from our experts.

Telegram: +98-915-55-20-388

WhatsApp: +98-915-55-20-388

Find Us on WeChat

What you’ll learn

What you’ll learn

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

Reviews

There are no reviews yet.