Material Calibration in Abaqus

Material calibration and Modeling of the material model is an important part of finite element analysis of a structure whose accuracy has a great impact on the accuracy and error of the analysis results. Data obtained from the results of physical tests applicable to FEA software is not always limited. Finite Element software such as the Abaqus has a good ability to model different materials. However, many models are still not usable in the Abaqus/CAE.

Tire Industry

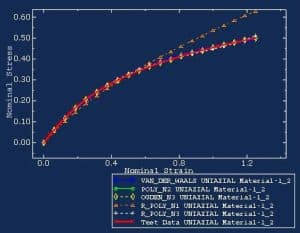

Material modeling is an important part of the finite element analysis of a structure whose accuracy has a great impact on the accuracy and error of the analysis results. FEA software such as Abaqus, Ansys, and LS-Dyna have a vast material model library. However, many material models are still not usable in the graphical environment or Abaqus/CAE. Due to the ability to solve nonlinearities in this software for a long time used in various industries such as the tire industry. The adoption and use of material models in the tire industry have led to the development and development of more up-to-date elastomer models and reinforced structures in this software. Nonlinear behaviors of elastomers include nonlinear elasticity (hyperelasticity), damage (Mullins effect), and viscoelastic behavior commonly seen in hysteresis loops. Thermal-mechanical coupling analysis may be required, in which case some models of thermomechanical materials can be readily available, and if there is no material model, the model can be developed by the user using Fortran subroutines.

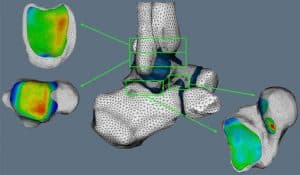

Medicine & Medical Engineering

Another industry where matter models matter is medicine and medical engineering. Design and manufacturing devices try to bring some of the ability back to the patients or be used in the field. Most of the material models used in this industry relate to the material of body tissue, muscle, cartilage, bone, and the like. Much research has been done to determine the mathematical equations of these materials. Many of these materials are now available in Abaqus and LS-Dyna.

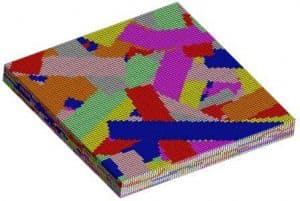

Micro and Nanoscale Modeling

Another area of research currently underway is the modeling of materials according to their structure at the molecular and nanoscale scale. Powerful BIOVIA software is most commonly used in this area. Recently, the modeling of composite and metallic materials at the micro-scale has been considered more. Modeling and breakdown analysis of these materials on a microscale can be implemented in different ways in the Abaqus. They have also been developed by individuals and companies to facilitate the simulation of several Abaqus plugins.

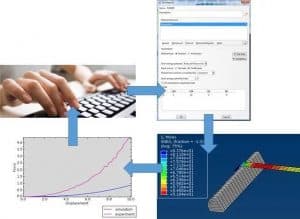

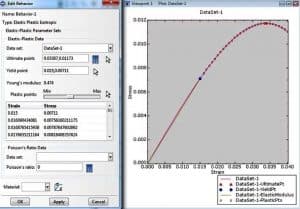

Calibration of Material Models

Working with each of the materials requires defining the material data obtained from the results of the experimental tests. This is a challenge when dealing with the nonlinear material. The information obtained from the calibration of materials applies to a variety of engineering applications such as ANSYS, ABAQUS, and LS-DYNA.

Contact us to determine material coefficients, calibration, and modification of material models in finite element analysis. experimental test data for many of the engineering materials are available at our company and have been used in various research and projects.

These include all kinds of foams, polymers, composites, ceramics, concrete, asphalt, and other building materials, metals, elastomers and rubbers, wood, and other materials used in various industries such as marine, aerospace and aerospace, and road construction. And related to construction, oil, gas and petrochemical, automotive, agriculture, mining, rail, packaging, and other related industries.

- Assess the sustainability of any material model for use in finite element analysis

- Possibility of performing virtual tests on different loading modes with different stress and strain time history

- Calibration of all kinds of construction and industrial materials

- Ability to use results in various engineering design software