What is Fitness for Service Analysis with Abaqus?

The Fitness for Service Analysis with Abaqus is a method in which the structure and its components are estimated to continue operating. The output of FFS is whether or not the equipment is operating. Estimating the remaining life or determining the time intervals required to inspect and eliminate and predict the cause of reduced material properties can be another output of this method.

Pipe fittings, pressure vessels, and tanks are periodically evaluated according to guidelines provided in documents such as ASME / API-579 Fitness-for-Service. The third level FFS, which is the finite element method (FEM) evaluation, is commonly used to study geometry and complex loading conditions.

Fitness For Service is a standard and practical method for determining the serviceability of various equipment in the industry. FFS examines the presence and extent of defects in a system based on various criteria.

This method has been used for pressure equipment with defects and damage since the 1960s. The two standards that are used intermittently in this method are ASME / API-579 Fitness-for-Service and BS 7910.

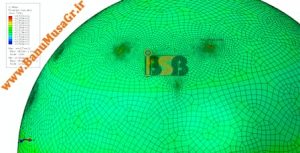

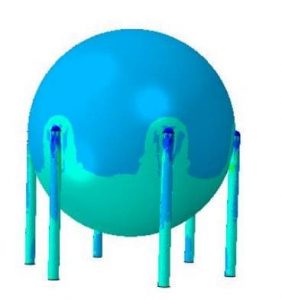

Portfolio: Level 3 fitness for service assessment of K.O.D with wall thinning using Abaqus & Signal FFS

Importance of Fitness-for-Service Analysis with Abaqus

Many companies are still unaware of the importance of FFS methods and prefer to do repairs using welding or the like. Periodic repairs to large volumes of equipment, such as platforms and refineries, are costly and expensive and may jeopardize the integrity of the structure. In Iran and the Middle East, due to the long life of most equipment used in various industries, this method is the cheapest and best way to determine their working life.

Why Fitness-for-Service Analysis with Abaqus?

- Determine the remaining life of damaged equipment

- Ensure the safety of equipment after their design life

- Proof of sufficient strength despite defects

- Increase inspection intervals

- Reduce downtime and shutdown of equipment

Most Important Defects Affecting Equipment & Structures

- Brittle Fracture

- General Metal Loss

- Local Metal Loss

- Pitting Corrosion

- Hydrogen blister

- Crack growth

- Fatigue

- Creep

- Stress corrosion cracking (SCC)

- Hydrogen brittleness

- Hydrogen attacks at high temperatures

- Damage caused by fire

- Hydrogen cracking

Fitness for Service Analysis with Abaqus Applications

- Heat exchangers and boilers

- Tubes

- Pressure stations

- A pipe connected to boilers

- Turbines

- Main pipes

- Storage containers

- Pressure Vessels

- Transmission pipes

- Reassurance valve

- Pumps

- Compressors

- Distillation towers

BanuMusa R&D engineers are ready to cooperate with your research and industrial consulting. This company is an expert and performer of Level 3 fitness for service (FFS) assessment for various equipment and cooperates with reputable inspection companies.