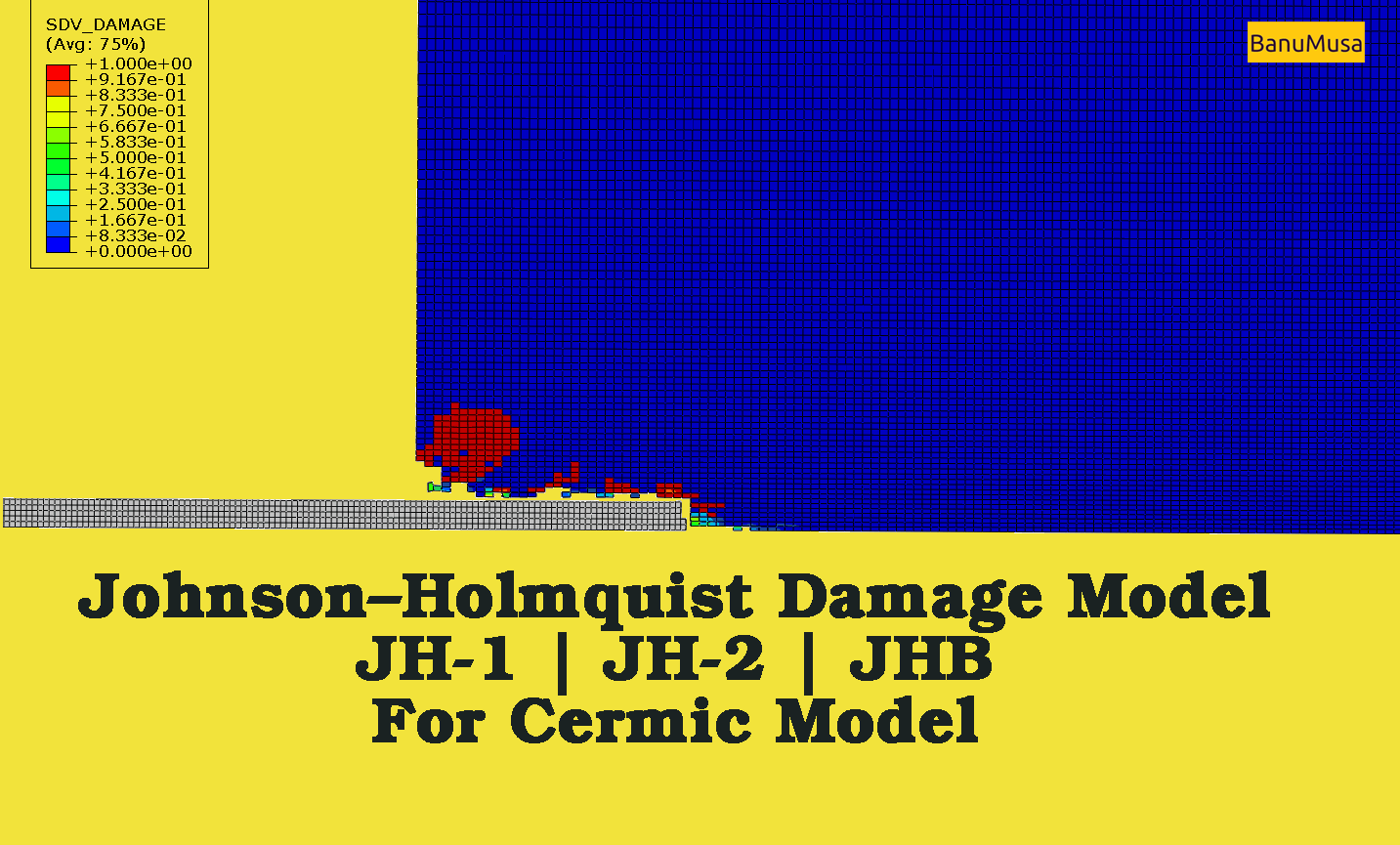

Abaqus VUMAT for the JHB and JH-2 Ceramic Model

VUMAT for the JHB and JH-2 Ceramic Model in ABAQUS

The purpose of the Abaqus VUMAT JHB and JH-2 Ceramic Model tutorial course is to learn, how to use Johnson-Holmquist (JH-2) and Johnson, Holmquist, and Beissel (JHB) built-in material models to simulate the failure behavior of brittle materials like ceramics.

With the release of Abaqus/Explicit 6.10 and later, two constitutive models for ceramics and other brittle materials are included as built-in material VUMATs:

- Johnson, Holmquist, and Beissel (JHB)

- Johnson and Holmquist (JH-2)

These models can be used to simulate the behavior of materials under high strain rate loading conditions, such as impacts.

Implementing Johnson-Holmquist Damage Models for Brittle Ceramics in Abaqus

The JHB and JH-2 models are continuum damage mechanics models used to simulate the failure of brittle ceramic materials. They are implemented in a VUMAT (user material) subroutine for Abaqus simulations to model the nonlinear behavior and damage of ceramics.

The JHB and JH-2 models are best suited for modeling the failure of brittle ceramic materials with linear elastic behavior up to failure and little or no plasticity. The VUMAT JHB and JH-2 ceramic models implement the constitutive model in Abaqus by calculating stresses, evolving damage, updating stiffness, and passing results to Abaqus at each increment.

To implement Johnson-Holmquist damage models for brittle ceramics in Abaqus, we suggest two solutions:

- Using the built-in material model in Abaqus

You have three choices for this. The JH-1, JH-2, and JHB models. All three models can be used in Abaqus without the need to write a VUMAT subroutine by defining a series of parameters in the Abaqus input file (*.inp). But if you want to develop your own VUMAT JHB and JH-2 ceramic models, the second solution is for you. - Writing a VUMAT subroutine

You do not need to write a subroutine! We have already done this for you. By preparing this package, you also receive a VUMAT subroutine Fortran file that includes the JH-2 ceramic model and you can easily use it with the linking of Abaqus software with Visual Studio and the Fortran compiler. Also, if you know a little more, you can develop your proposed model by making changes in the formulation of JH-2. In this way, you save a lot of coding and research time.

What you’ll learn

- What are the Johnson, Holmquist, and Beissel (JHB) And Johnson-Holmquist (JH-2) ceramic models?

- What are the VUMAT JHB and JH-2 ceramic models’ damage parameters?

- Where and for what materials, VUMAT JHB and JH-2 ceramic models can be used?

- How to define and use Abaqus VUMAT JHB and JH-2 ceramic models in Abaqus?

- What is Hugoniot elastic limit in VUMAT JHB and JH-2 ceramic models?

- Set up Abaqus CAE for built-in VUMAT JHB and JH-2 ceramic models subroutine

- Define the damage behavior of brittle materials in Abaqus

- Define field variables for the VUMAT JHB and JH-2 ceramic models in Abaqus

- How to determine the required VUMAT JHB and JH-2 ceramic models parameters from physical tests

- How to define the VUMAT JHB and JH-2 ceramic models in an Abaqus input file

- Run Abaqus with built-in VUMAT JHB and JH-2 ceramic models

- Perform single-element analysis with/without VUMAT subroutine

- Simulate high-velocity impact in Abaqus

- Visualize the damage/stress/displacement/strain results

Overview of VUMAT JHB and JH-2 Ceramic Model Course

- Introduction to VUMAT JHB & JH-2 ceramic model

- Abaqus VUMAT JHB & JH-2 ceramic model parameters

- Modeling ceramic failure with the JHB and JH-2 continuum damage mechanics models

- Implementing Johnson-Holmquist damage models for brittle ceramics in Abaqus

- Examples & workshops

- Additional modeling issues

- Limitations

Examples & Workshops

Examples & Workshops

- Workshop 1: JH-2 single-element tests

- Workshop 2: JHB single-element tests

- Workshop 3: High-velocity impact of a ceramic target (JHB built-in material model)

- Workshop 4: High-velocity impact of a ceramic target (JH-2 built-in material model)

- Workshop 5: High-velocity impact of a ceramic target (Drucker-Prager material model)

- Workshop 6: High-velocity impact of a ceramic target (JH-2 VUMAT subroutine)

Here you can find an example in Abaqus documentation

Who this course is for

- Civil and mechanical engineers who need to perform high-velocity impact analysis

- Advanced students, Ph.D. students, or researchers for their Abaqus FEA projects

- Any Abaqus Application Engineer who is involved with various simulation projects on a daily basis

- Design and research and development (R&D) offices of military and parts manufacturing companies

- Abaqus FEA simulation consultancies

What you’ll gain

- You will be able to conduct high-velocity impact analysis by Abaqus

- You will be able to develop your own Abaqus VUMAT user subroutine of the Johnson-Holmquist damage model

Need help? Get a consultation from our experts.

Telegram: +98-915-55-20-388

WhatsApp: +98-915-55-20-388

Examples & Workshops

Examples & Workshops We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at  A VUMAT subroutine in Abaqus is a user-defined material model. It allows you to define custom material behaviors that are not available in the standard Abaqus material models.

A VUMAT subroutine in Abaqus is a user-defined material model. It allows you to define custom material behaviors that are not available in the standard Abaqus material models.

Reviews

There are no reviews yet.