Modeling Rubber and Viscoelasticity with Abaqus

The Modeling Rubber and Viscoelasticity with Abaqus training course delves into crucial aspects of rubber and viscoelastic behavior. It offers a thorough grasp of these principles through real-life instances and interactive activities, equipping learners to effectively confront modeling difficulties in their engineering endeavors.

This course is structured with lectures, demonstrations, and workshops. The workshops are crucial for the training as they aim to solidify the ideas covered in the lectures and demonstrations. Their purpose is to give participants hands-on experience in conducting and troubleshooting real engineering problems.

What you’ll learn

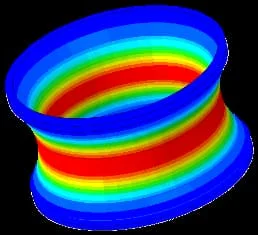

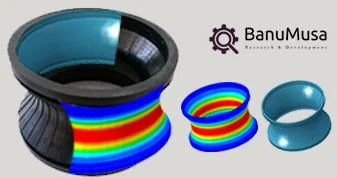

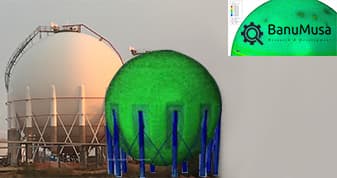

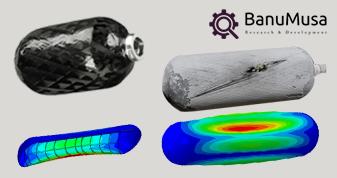

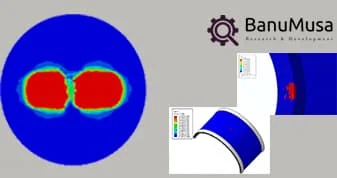

In this course, you will learn about materials such as rubber and resilient foam which are commonly modeled as nonlinear elastic. This course typically covers topics such as finite element analysis, Hyperelastic material models, material data calibration, and writing its user material subroutines within Abaqus.

Upon successfully finishing this course, every participant will have the ability to:

- Utilize test data in experiments to determine material constants

- Assess the stability of the Abaqus material model under high strains

- Derive optimal material parameters from the test data on hand

- Choose suitable elements for simulating rubber and foams

- Create a suitable finite element mesh

- Simulate viscoelastic properties in both time and frequency domains

- Implement a user subroutine to specify hyperelastic behavior

Overview of the course

Lecture 1 Introduction to Polymers/Elastomers

- Introduction

- What is a Polymer?

- Polymer Types

- Rubber Physics

Lecture 2 Introduction to Hyperelasticity Models

- Choosing a Strain Energy Function

- Isotropic Hyperelasticity Models

- Neo-Hookean Model

- Arruda-Boyce Form

- Marlow Form

- Mooney-Rivlin Model

- Yeoh Model

- Eight-Chain Model

- Ogden Model

- Polynomial Form

- Gent Model

- Van der Waals Form

- Yeoh Form

- Anisotropic Hyperelasticity Models

- Strain-based Formulation – Generalized Fung form

- Invariant-based Formulation – Holzapfel, Gasser, and Ogden form

- User-defined Form: Invariant-based

- Hyperelastic Foam Models

- Hyperfoam Model

- Mullins Effect Models (damage due to straining)

- Ogden-Roxburgh Mullins Effect Model

- Workshop – Cyclic analysis of axial flow valve sleeve

Lecture 3 Mechanical Behavior of Elastomers

- Experimental Characterization Techniques

- Mechanical Testing for Material Model Calibration

- Mechanical Testing for Material Model Validation

- Workshop – Axial Deflection of a Rubber Bushing

Lecture 4 Hyperelastic Material Model for FEM

- Introduction

- Required Inputs for FEA

- Material Stability

- Abaqus Rubber Material Model

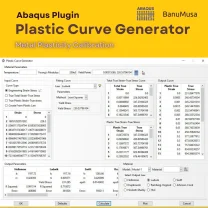

- Curve Fitting

- Evaluating Hyperelastic, Hyperfoam, and Viscoelastic Material Behavior

- Defining a UHYPER user subroutine – Example

- Modeling Techniques

Lecture 5 Modeling Considerations and Usage Tips in Abaqus

- Workshop – Bead Seal Compression

Lecture 6 Viscoelastic Material Behavior

- Introduction

- Hysteresis Material Model

- Bergstrom-Boyce Hysteresis Model – Abaqus/Explicit VUMAT Built-in Model

Lecture 7 Time-Domain Viscoelasticity

- Workshop – Bead Seal Relaxation

Lecture 8 Frequency-Domain Viscoelasticity

- Workshop – Bead Seal Vibration

Lecture 9 User Material Subroutines

- Introduction to User Material Subroutines

- Neo-Hookean Model – Abaqus/Explicit VUMAT

- Neo-Hookean Model – Abaqus/Implicit UMAT

- Incompressible Hyperelastic Model – Abaqus/Implicit UHYPER

– Appendixes

- Linear Viscoelasticity Theory

- Fatigue of Hyper-elastic Materials (related blog: Performing Fatigue Analysis in Abaqus)

- Introduction to fe-safe/rubber plugin

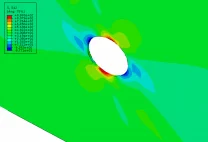

- Workshop – Tension on a Plate with Hole

Knowledge Prerequisites

Suggested for engineers who have familiarity with Abaqus.

Who Should Attend

Those engaged in the design, analysis, or manufacture of elastomer parts such as seals and gaskets, shock mounts, vibration isolators, and tires may benefit from having some technical knowledge. However, possessing an Engineering degree or prior work experience in the field is not mandatory.

This course is available offline with 24/7 online support.

A certificate of completion will be provided to participants who successfully attend and finish the course.

Targeted Audience

- Mechanical Engineers

- Simulation Analysts

- Abaqus Application Engineers

- Abaqus Users

- Safety, Reliability, and Quality Engineers

Available Releases

2024

Duration

12 hours

Discipline

Modeling Rubber and Viscoelasticity with Abaqus Course is designed to cover the utilization of Abaqus for FE analysis of rubbers, foams, and other viscoelastic materials. It is aimed at engineers involved in FEA simulation who wish to enhance their comprehension of the intricate mechanical and failure behavior associated with rubbers.

Virtual Mentoring Platform:

Skype+AnyDesk is BanuMusa’s interactive online mentoring solution with the most reliable features to help you before, during, and after your sessions. it is a robust training platform that engages students/attendees virtually.

Cancellation Policy:

A full refund is available for cancellations more than 30 days before the course recording start date. Within 30 days of the course start date, course credit can be transferred to another attendee within the same company, or can be kept on file to be applied to a future BanuMusa training course.

Need help? Get a consultation from our experts.

Telegram: +98-915-55-20-388

WhatsApp: +98-915-55-20-388

Find Us on WeChat

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at  After the end of the course, a Certificate of Completion will be awarded to you by BanuMusa R&D.

After the end of the course, a Certificate of Completion will be awarded to you by BanuMusa R&D.

Reviews

There are no reviews yet.