Porous Elastomers Abaqus UHYPER Subroutine

The Abaqus material model library does not have a material model for porous elastomers. For this purpose, in order to model and analyze these materials, it is necessary to write the constitutive model of the material in a user subroutine. In Abaqus, the UHYPER subroutine is the best option for defining the hyperelastic material model. To avoid wasting your time with writing subroutines, you can use Porous Elastomers Abaqus UHYPER Subroutine. Along with the UHYPER subroutine, several examples are included to ensure the accuracy of the code.

Hyperelastic Material Models

Modeling porous elastomers in Abaqus requires using a hyperelastic material model along with a user subroutine to define the porous material behavior. Abaqus has several hyperelastic material models that are well-suited for modeling elastomers and rubber-like materials. These models define the stress-strain behavior using strain energy potential functions instead of elastic moduli. Common hyperelastic material models in Abaqus include:

- Neo-Hookean

- Ogden

- Mooney-Rivlin

- Yeoh

- Marlow

- Arruda-Boyce

- Van der Waals

- Polynomial form

To capture the effects of porosity on the hyperelastic material behavior, a user subroutine is needed.

What Is UHYPER User Subroutine?

A UHYPER user subroutine is a user-defined hyperelastic material model subroutine in Abaqus. Abaqus has several built-in hyperelastic material models to represent the nonlinear behavior of rubber-like materials. However, these standard models often cannot adequately capture the full stress-strain behavior of certain materials.

A UHYPER subroutine allows users to define a custom hyperelastic material model to more accurately represent a specific material’s behavior. A UHYPER subroutine defines as:

- A user-defined strain energy potential function – The strain energy potential function (W) defines the strain energy stored in the material as a function of the strain invariants.

- Derivatives of the strain energy potential – The 1st and 2nd derivatives of W with respect to strain invariants, which are needed to calculate stress and elasticity tensors.

- Additional data – The UHYPER subroutine can also define additional material properties, damage variables, temperature dependence, etc.

A UHYPER subroutine allows you to more accurately model the hyperelastic behavior of soft materials that cannot be modeled well using Abaqus’ standard hyperelastic material models alone. The user-defined strain energy potential function can capture any nonlinearities and anisotropy in the actual material’s behavior.

What Are Porous Elastomeric Materials?

Porous elastomeric materials are a class of rubber and polymer materials that have a cellular structure with voids, pores, or holes within the material. Porous elastomeric materials are widely used in industrial and commercial applications, especially as shock absorbers, dampers, packaging materials, etc.

Oftentimes these applications involve very large deformations of the material. From a product design and performance perspective, engineers are usually interested in the macroscopic response of these materials and their interaction with other components in an assembly. Appropriate modeling of the macroscopic mechanical response of these materials under arbitrarily large deformations is, therefore, the main requirement for engineering applications.

Constitutive Model

Several constitutive models have been proposed in recent years to describe the macroscopic elastic response of porous elastomers based on homogenization solutions. Among those, the model proposed by Shrimali et al. is remarkably simple, accurate, and very suitable for implementation in Abaqus using the UHYPER user subroutine.

Examples & Workshops

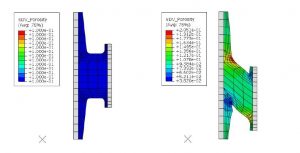

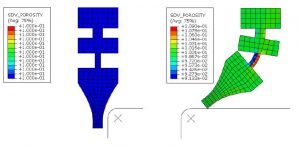

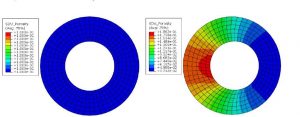

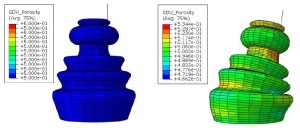

To demonstrate the applicability of the UHYPER user subroutine, several practical examples are presented which are based on models already available in the Abaqus Example Problems Manual. The details of the model setup can be found in the product.

| Example 1: Rubber bushing model |  |

| Example 2: Windshield wiper model |  |

| Example 3: Viscoelastic bushing model |  |

| Example 4: Automotive boot seal model |  |

| Example 5: Automotive boot seal model – 2 Dimensional |

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

Reviews

There are no reviews yet.