API 579-1/ASME FFS-1 Fitness-For-Service Evaluation Course

Fitness-for-service evaluation is an interdisciplinary engineering approach used to determine if the equipment is suitable for continued operation until the next inspection or replacement. The equipment might have flaws, sustained damage, or aged to a point where it no longer meets the requirements of the original construction code. API 579-1/ASME FFS-1 is a comprehensive industry standard that can be employed to analyze, evaluate, and monitor equipment for ongoing operation, with a focus on pressure vessels, piping, and atmospheric storage tanks.

API 579-1/ASME FFS-1 Fitness-For-Service Evaluation Course aims to help participants grasp and implement the API/ASME fitness-for-service standard in their daily tasks. The course material demonstrates how stress analysis, materials engineering, and nondestructive inspection disciplines interact and are applied to fitness-for-service assessments on in-service pressure vessels, piping, and tanks. While the course covers all aspects of the API579/ASME FFS-1 standard, it does not include the standard itself.

Included in the course are detailed notes to complement the standard’s content, along with numerous example problems to illustrate fitness-for-service assessments.

What is FFS?

Fitness-for-Service (FFS) assessment involves a comprehensive method that assesses structural elements to ascertain their suitability for ongoing use.

This course is structured with lectures, demonstrations, and workshops. The workshops are crucial for the training as they aim to solidify the ideas covered in the lectures and demonstrations. Their purpose is to give participants hands-on experience in conducting and troubleshooting real FFS analyses.

FFS Assessments

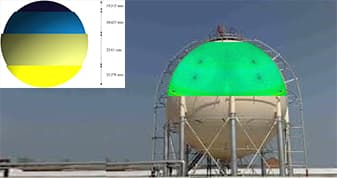

The API 579/ASME FFS-1 Fitness-For-Service method defines three assessment levels. If Level 1 criteria aren’t met, a repair or Level 2 assessment is needed. If Level 2 criteria aren’t met, a repair/replacement or Level 3 assessment is necessary. The higher the level, the more information and experience the assessing engineer needs.

Level 1: Basic inspection data and a screening curve, can be done by a plant inspector or engineer.

Level 2: Less conservative than Level 1, requires detailed data and more complex calculations, must be done by a plant engineer or specialized engineer.

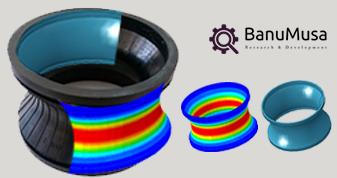

Level 3: Requires a highly experienced engineer due to advanced analysis and judgment, may involve stress analysis or complex finite element analyses, sometimes leading to repair or replacement.

What you’ll learn

In this FFS evaluation course, you will learn about FFS Analysis using API579.

Upon successfully finishing this course, every participant will have the ability to:

- Examine, assess, and oversee the ongoing operation of pressure vessels, piping, and tanks.

- Describe the utilization of foundational knowledge in fitness-for-service evaluation, particularly about the refining and chemical process sectors, which are the key areas of focus in API 579.

- Identify the primary sections of the API/ASME standard, along with its annexes.

- Illustrate the practical implementation of the methodologies outlined in API 579-1/ASME FFS-1.

As part of the course, The downloadable version of API 579 standard will be available, at no cost.

Overview of the course

Lecture 1 Introduction to Fitness-for-Service

- ASME/API-579 Fitness-for-Service (FFS) Overview

- Scope and Objectives

- General Roadmap

- FFS assessment procedures

- Responsibilities in FFS

Lecture 2 Brittle Fracture

Lecture 3 General Metal Loss

Lecture 4 Local Metal Loss

Lecture 5 Pitting Corrosion

Lecture 6 Hydrogen Blisters and Hydrogen Damage Associated with HIC and SOIC

Lecture 7 Weld Misalignment and Shell Distortion

Lecture 8 Crack-Like Flaws

Lecture 9 Creep

Lecture 10 Assessment of Dents and Gouges

Lecture 11 Assessment of Laminations

Lecture 12 Fatigue

XX- Level 3 Fitness-For-Service Examples and Advanced Analyses

Knowledge Prerequisites

None

Who Should Attend

This course targets engineers and engineering managers involved in operating, designing, analyzing, and maintaining plant facilities. Participants should possess a Bachelor of Science degree or equivalent engineering experience. A basic understanding of stress analysis, materials behavior, and fracture mechanics is advantageous.

This course is available offline with 24/7 online support.

A certificate of completion will be provided to participants who successfully attend and finish the course.

Targeted Audience

- Integrity Assessment Engineers

- Maintenance Engineers

- Site Inspection Engineers

- Piping Engineers

- Mechanical Engineers

- Plant Engineers

- Fixed–Equipment Reliability Engineers

- Simulation Analysts

- FFS Engineers

- Welding Engineers

- Operational Personnel

- Process Engineers

- Project Managers

- HSEQ Personnel

Available Releases

2024

Duration

5 hours

Discipline

API 579-1/ASME FFS-1 Fitness-For-Service Evaluation Course is designed to cover the utilization of level 1, 2, and 3 API 579 FFS analysis. It is aimed at engineers involved in FFS assessment who wish to enhance their comprehension of the intricate mechanical and failure behavior associated with plant facilities.

Need help? Get a consultation from our experts.

Telegram: +98-915-55-20-388

WhatsApp: +98-915-55-20-388

Virtual Mentoring Platform:

Skype+AnyDesk is BanuMusa’s interactive online mentoring solution with the most reliable features to help you before, during, and after your sessions. it is a robust training platform that engages students/attendees virtually.

Cancellation Policy:

A full refund is available for cancellations more than 30 days before the course recording start date. Within 30 days of the course start date, course credit can be transferred to another attendee within the same company, or can be kept on file to be applied to a future BanuMusa training course.

Find Us on WeChat

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at

We’re fully confident in the value and reliability of the product. If for any reason you are not completely satisfied, email us at  After the end of the course, a Certificate of Completion will be awarded to you by BanuMusa R&D.

After the end of the course, a Certificate of Completion will be awarded to you by BanuMusa R&D.

Reviews

There are no reviews yet.