If you require further information, please feel free to reach out to us or send an email to info@banumusagr.com. Your feedback is valuable to us and we look forward to hearing from you.

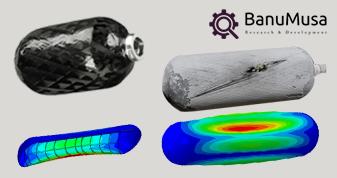

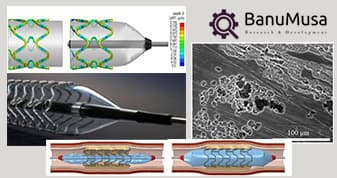

FEA-Enhanced Medical Stent

FEA-enhanced medical stent represents a significant leap forward in the field of interventional cardiology, offering healthcare professionals and patients alike a reliable and innovative solution for complex cardiovascular conditions.

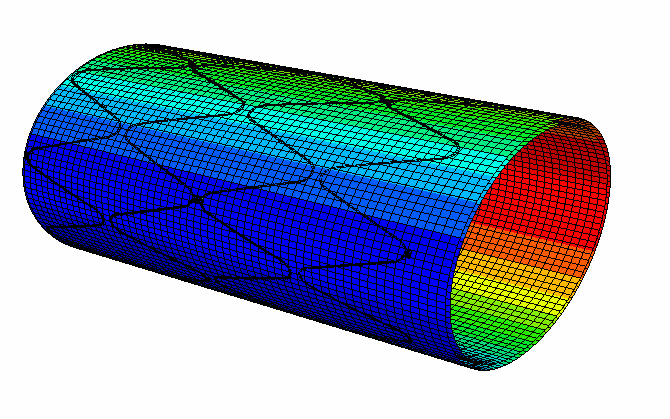

By integrating advanced Finite Element Analysis (FEA) techniques, our team has developed a groundbreaking approach to enhancing medical stent design. Through meticulous simulation and analysis, we have optimized the stent’s structural integrity, biomechanical performance, and material composition, ensuring superior efficacy and patient safety.

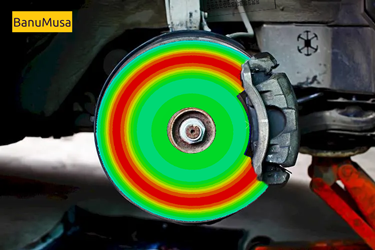

Our portfolio showcases our expertise in optimizing medical stents’ performance through Finite Element Analysis (FEA). FEA allows us to simulate and analyze the behavior of medical stents under various conditions, enabling us to enhance their design for better performance and durability.

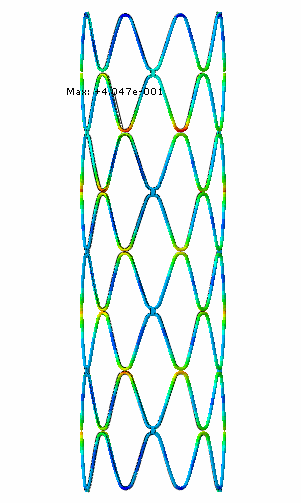

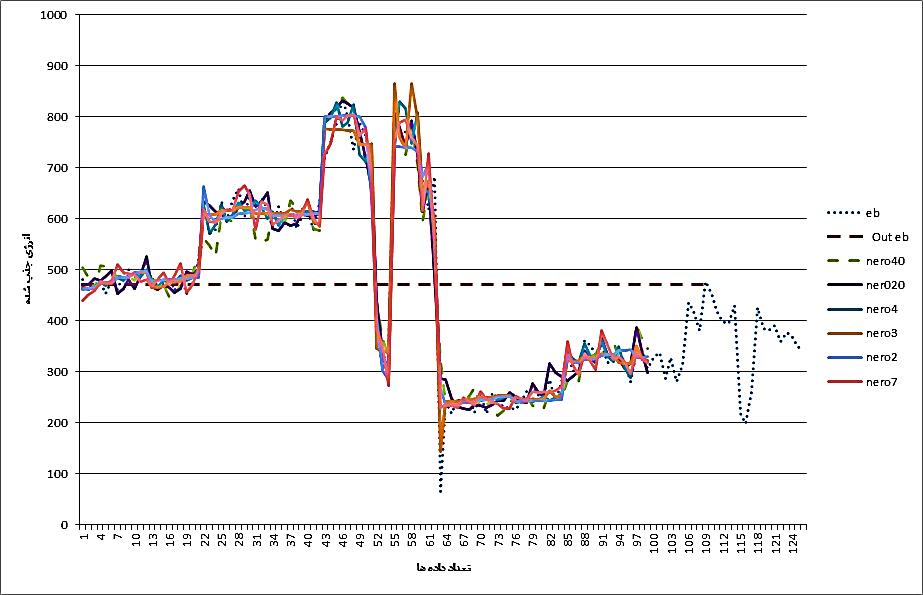

We have successfully utilized FEA to optimize the mechanical properties of medical stents, ensuring that they can withstand the complex loading conditions within the human body. By accurately predicting stress, strain, and deformation, we can fine-tune the design of stents to meet the specific requirements of different anatomical locations and patient needs.

Our projects demonstrate our ability to improve the performance of medical stents by leveraging FEA to optimize their structural integrity, flexibility, and fatigue resistance. Through our expertise in FEA analysis, we have contributed to developing stents that offer superior clinical outcomes and long-term reliability.

With a focus on innovation and precision engineering, our portfolio highlights our commitment to advancing medical stent technology through FEA-enhanced design and optimization.

Benefits of Using Finite Element Analysis for Stent Evaluations

• Accurately representing the stent’s shape and its complete load history

• Assisting in defining the manufacturing processes associated with expansion and annealing

• Evaluating various stent structures for deformations, stresses, and strains, and estimating fatigue life

• Understanding the impact of balloon/stent interaction during deployment

• Simulating the interaction between the device and the vessel during stent placement and deployment

• Identifying locations of peak stress/strain that may adversely affect safety and effectiveness

• Predicting the response of the implanted/deployed device to fatigue loading