FMEA Stands for

FMEA stands for Failure Mode and Effects Analysis. It is a structured approach used to identify and evaluate potential failures or risks in a system, product, or process.

FMEA stands for Failure Mode and Effects Analysis. It is a structured approach used to identify and evaluate potential failures or risks in a system, product, or process.

There are many examples of feedback due to improper product design. Product failure can be caused by a series of mistakes during engineering design, production, material supply, quality control, distribution, and other production cycle processes.

DFMEA vs PFMEA

There are a total of two categories of FMEA: DFMEA and PFMEA.

Design Failure Mode and Effects Analysis

DFMEA stands for Design Failure Mode and Effects Analysis. It is a structured approach used to identify and analyze potential design failures, their causes, and their effects on the system or product. It focuses on the design of the product and how potential failures can be prevented or mitigated through design changes.

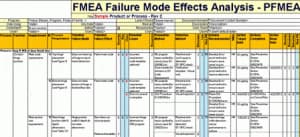

Process Failure Mode and Effects Analysis

On the other hand, PFMEA stands for Process Failure Mode and Effects Analysis is used during the manufacturing process to identify potential failure modes and their effects on the manufacturing process. It focuses on the manufacturing process and how potential failures can be prevented or mitigated through process changes.

FMEA vs FEA

FEA stands for Finite Element Analysis, which is a numerical technique for finding approximate solutions to boundary value problems for partial differential equations. It is commonly used in engineering to simulate the behavior of structures, components, and systems under various conditions.

However, FMEA is focused on identifying and mitigating potential failure modes, while FEA is a computational method for analyzing the behavior of physical systems.

It should be noted, that FEA can be used as a tool in FMEA.

FMEA in Industry

Failure Mode and Effects Analysis is a widely used methodology to identify, analyze, and mitigate potential failures in a product or process. It is commonly used in various industries to improve the quality and reliability of their products and services.

Some of the industries that commonly use it include:

Automotive industry: it is widely used in the automotive industry to identify potential failures in vehicles, such as engine failures, brake failures, etc.

Aerospace industry: it is also widely used in the aerospace industry to identify potential failures in aircraft systems, such as avionics, landing gear, etc.

Medical device industry: it is commonly used in the medical device industry to identify potential failures in medical devices, such as pacemakers, insulin pumps, etc.

Manufacturing industry: it is also used in the manufacturing industry to identify potential failures in manufacturing processes, such as assembly lines, welding processes, etc.

Food industry: it is used in the food industry to identify potential hazards in food production processes, such as contamination, spoilage, etc.

Marine industry: it is used in the marine industry to improve safety and reduce risks associated with marine operations. It is used during the design phase of a vessel or marine system, as well as during maintenance and operation.

Oil & gas industry: In the oil and gas industry, it can be applied to various aspects of operations, such as drilling, production, transportation, and refining. For example, it can be used to identify potential failures in drilling equipment that could lead to well blowouts or oil spills. It can also be used to assess the risks associated with transporting hazardous materials or operating high-pressure pipelines.

Rail industry: In the railway industry, it is used to identify potential failures in trains, tracks, signaling systems, and other components to prevent accidents and improve safety.

Recently FMEA Projects

Our services

- Failure analysis

- Fitness for service (FFS) assessment

- Risk-based inspection (RBI)

- Finite element analysis (FEA)

- Computational fluid dynamics (CFD)

- Design by analysis

Technology

BanuMusa is an FMEA consultant, contact us to learn more